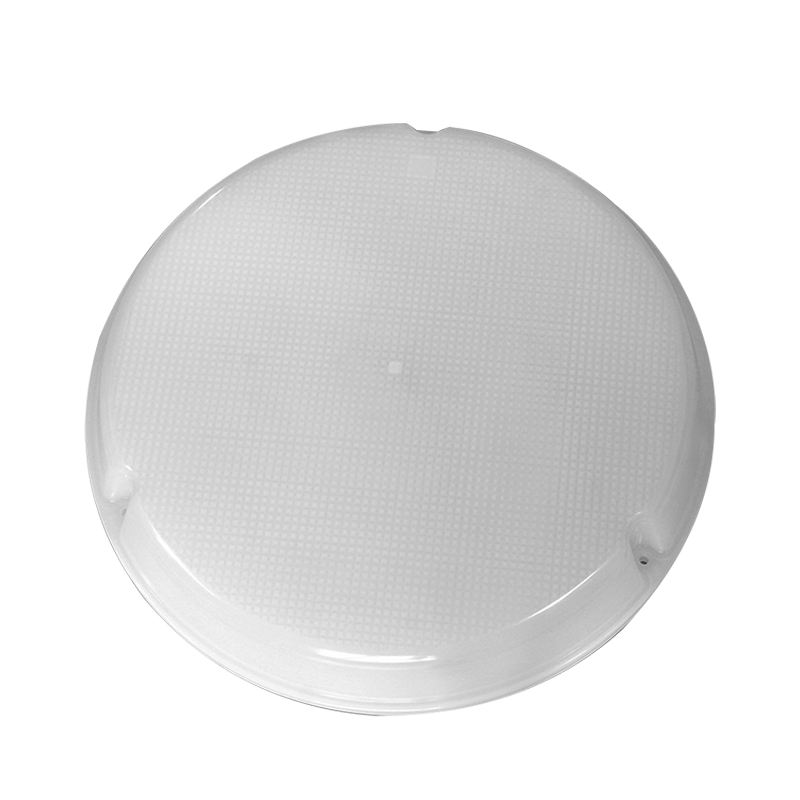

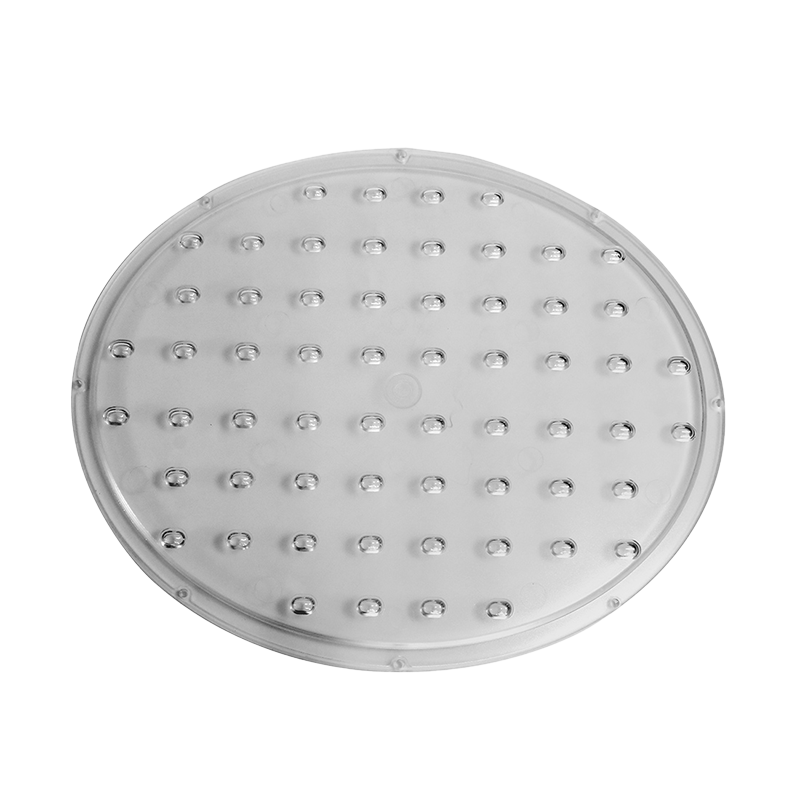

Frosting treatment forms a micron-level concave-convex structure on the surface of the plastic lighting lampshade, decomposing the incident light into multi-angle scattered beams. This non-directional reflection characteristic makes the light diffuse evenly, avoids direct light spots, and significantly improves visual comfort. For example, plastic lighting lampshades for bedrooms often use frosting technology to convert strong light into soft ambient light to create a warm atmosphere.

The difference in surface roughness directly affects the shadow performance of plastic lighting lampshades: the coarse frosted surface can weaken the hard shadow boundary and is suitable for creating a three-dimensional sense; the fine frosted surface retains a moderate light and dark contrast and is suitable for display scenes that require visual guidance. In addition, the thickness of the frosted layer is negatively correlated with the transmittance, and the process parameters need to be balanced according to the light transmittance requirements of the plastic lighting lampshade.

Frosted plastic lighting lampshades can eliminate glare and protect eyesight, especially suitable for areas such as children's rooms and reading corners. Through local frosting treatment, plastic lighting lampshades can achieve the integration of key lighting and atmosphere lighting, such as clothing store windows and restaurant chandeliers.

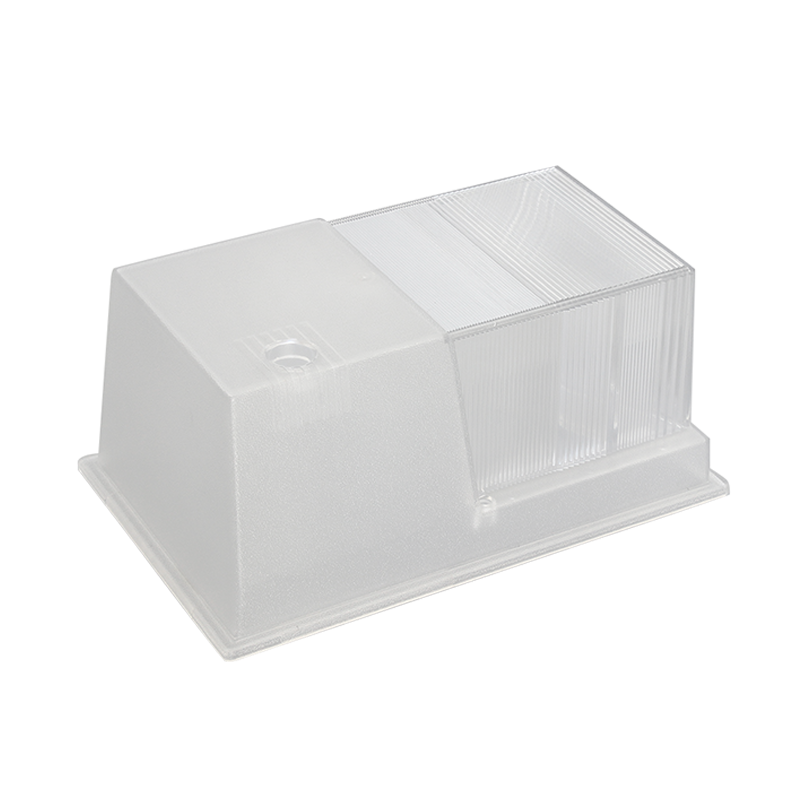

Spraying technology deposits functional coatings on the surface of plastic lighting shades to achieve precise control of light effects. For example, anti-fog coatings can reduce the interference of water vapor condensation on light, ensuring that plastic lighting shades remain clear and transparent in humid environments; matte coatings make light softer by reducing surface reflectivity.

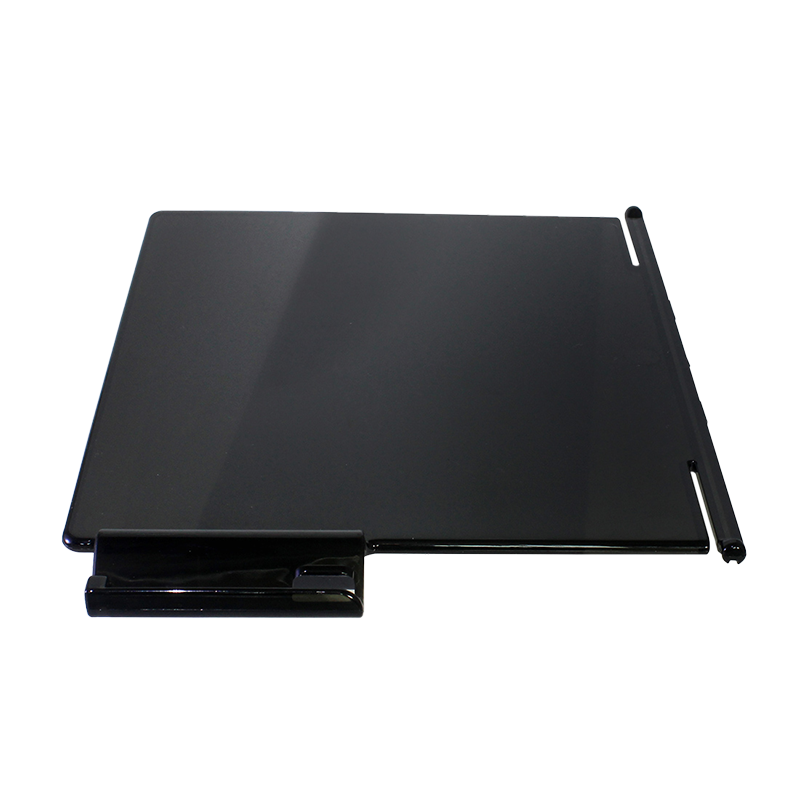

Spraying technology gives plastic lighting shades a rich variety of color options and texture performance: high-gloss coatings can enhance the modern feel of plastic lighting shades and are suitable for high-tech style lamps; metal texture coatings can enhance the decorativeness of plastic lighting shades and replace some metal materials to reduce costs.

Spraying defects will directly affect the light uniformity of plastic lighting shades. Optimizing the spraying environment, adjusting the viscosity of the paint and the parameters of the spray gun can significantly improve the yield rate. In addition, the use of two-component coatings or UV curing technology can enhance the adhesion of the coating and extend the service life of the plastic lighting shade.

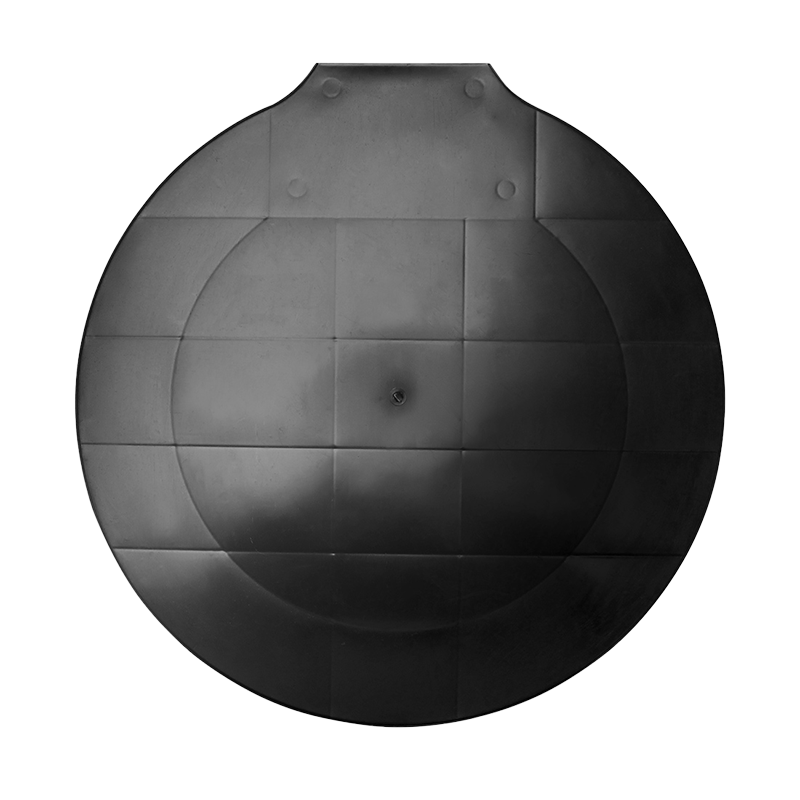

The electroplating layer significantly improves the light utilization rate of the plastic lighting shade through its high reflectivity characteristics. For example, the vacuum aluminum plating process can form a mirror reflection layer on the surface of the plastic lighting lampshade, which can focus the light to the target area. It is suitable for scenes that require high-brightness lighting, such as display cabinets and jewelry stores.

The electroplating process not only improves the optical performance of plastic lighting lampshades, but also enhances their decorative value through the metallic texture. Some high-end plastic lighting lampshades adopt a local electroplating design to enhance the reflective effect in key areas while retaining the lightweight advantage of plastic materials.

The uniformity of the electroplating layer directly affects the light quality of the plastic lighting lampshade. The coating thickness, adhesion and corrosion resistance need to be strictly monitored to avoid defects such as missing plating and yellowing. In addition, the electroplating pretreatment is crucial to the adhesion of the plastic substrate, and the process parameters need to be adjusted according to the type of plastic.

English

English Español

Español 简体中文

简体中文