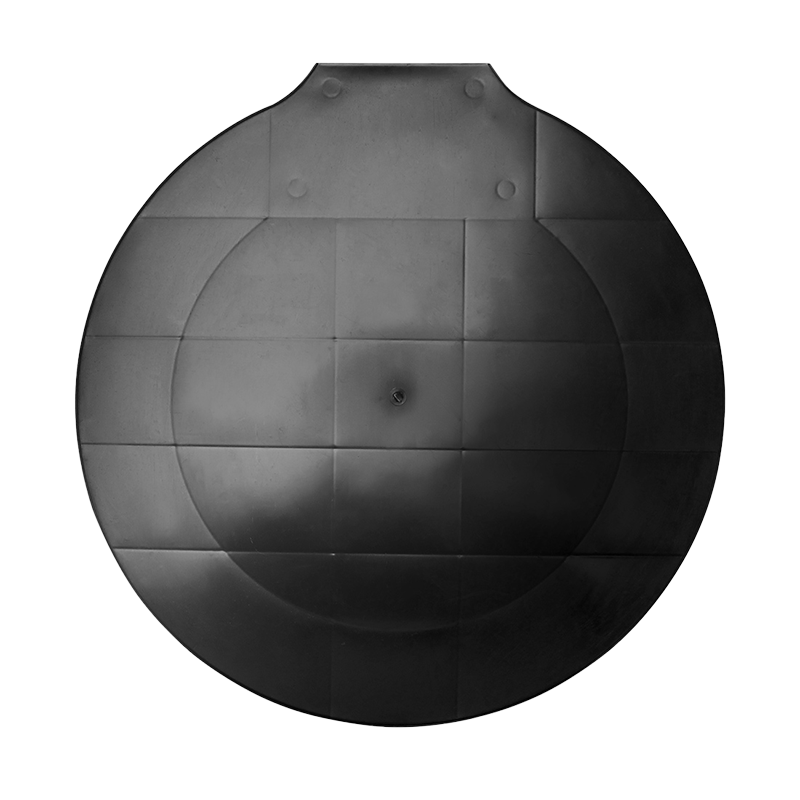

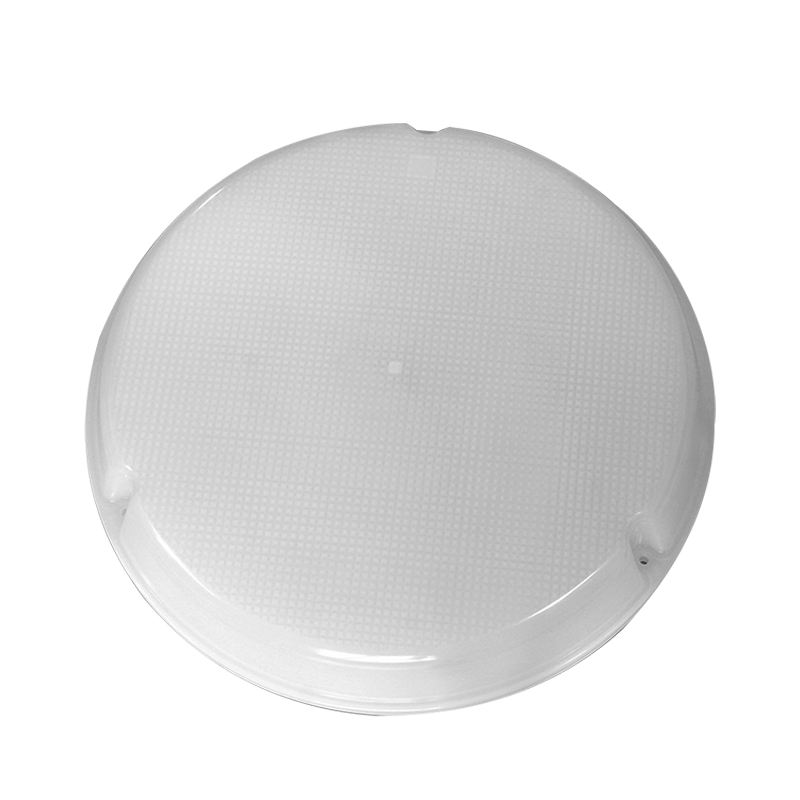

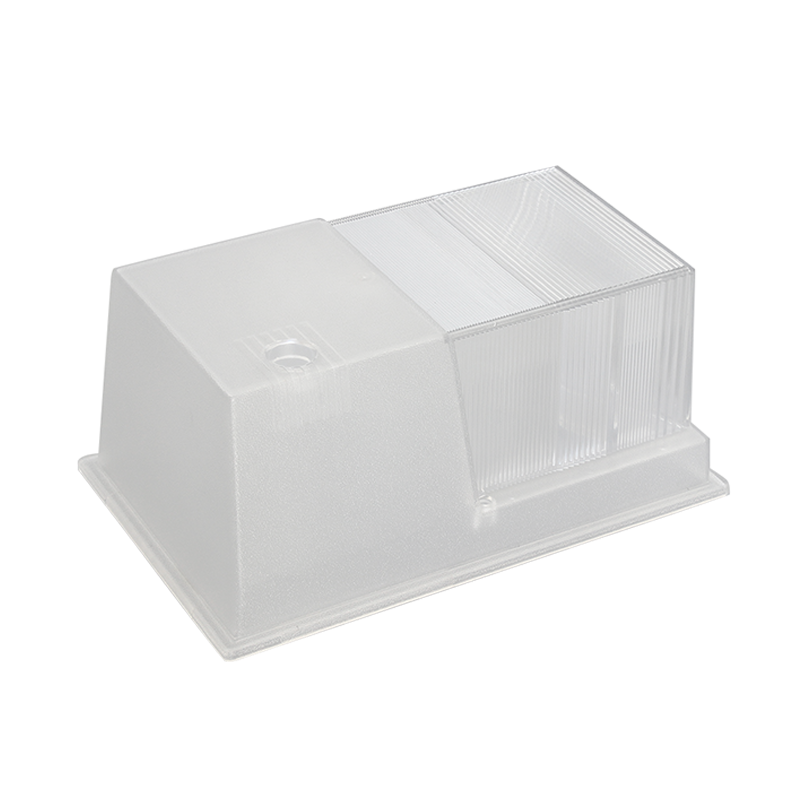

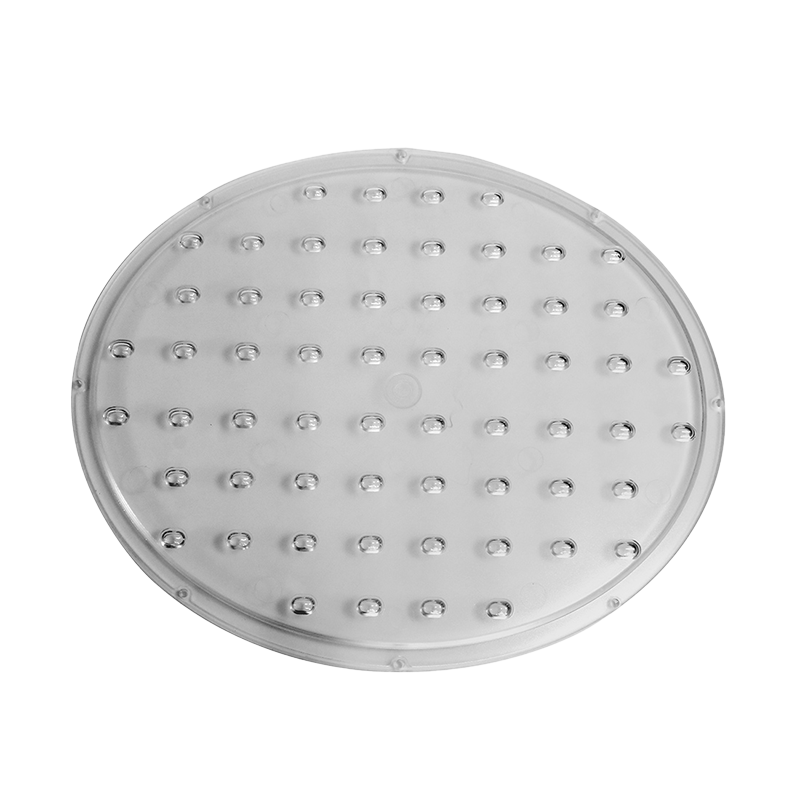

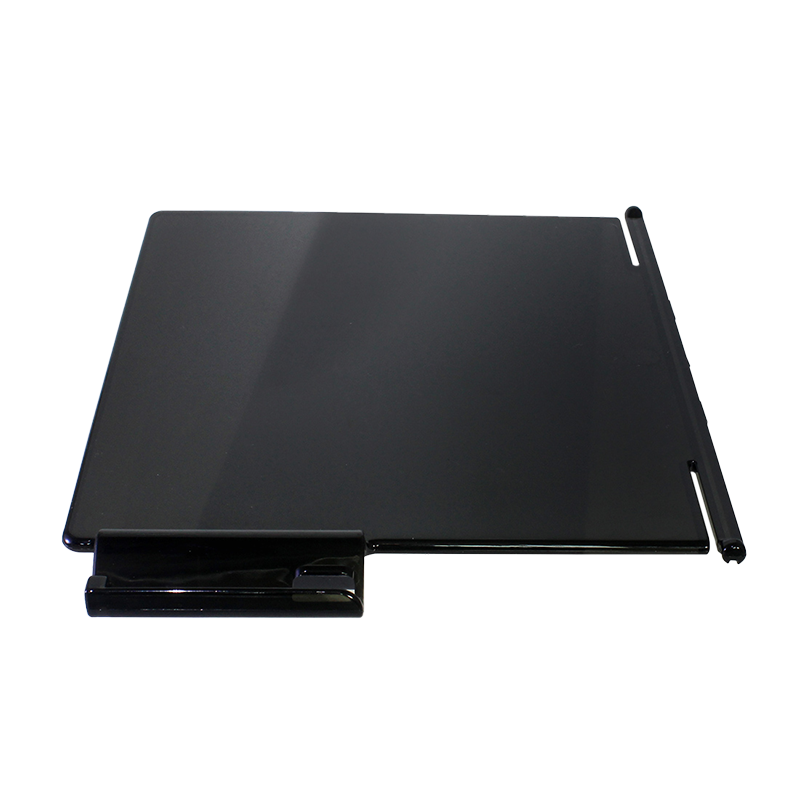

Plastic Lighting Lampshade is a key component of lighting equipment, and the technology used in its manufacturing process directly affects the appearance, performance and quality. In this regard, injection molding technology plays a key role in the manufacturing of Plastic Lighting Lampshade, giving it the advantages of complex geometries and high-precision molding.

Injection molding technology is a molding process in which molten plastic material is injected into a mold and formed into the desired shape after cooling. This process can efficiently and accurately replicate the details of the mold and is suitable for manufacturing complex-shaped products such as Plastic Lighting Lampshade.

Plastic Lighting Lampshades often require various unique and complex geometric shapes to achieve good distribution and refraction of lighting effects. Injection molding technology can accurately restore the designer's intention through precision design of the mold and high-pressure injection, allowing the lampshade to present diverse and detailed shapes.

In lighting equipment, the high precision of the lampshade is the key to ensuring uniform light distribution and overall lighting effect. Injection molding technology ensures that the size and shape of each Plastic Lighting Lampshade can meet the design requirements through a highly automated production process, ensuring consistent quality.

Injection molding technology not only enables high-precision molding, but also shows significant cost-effectiveness in mass production. Due to its high degree of automation and rapid molding speed, large quantities of Plastic Lighting Lampshade can be produced in a shorter period of time, thereby reducing production costs.

In today's era of emphasis on sustainable development, injection molding technology also has the advantage of being environmentally friendly. By rationally selecting recyclable plastic materials and optimizing the production process, the impact on the environment can be reduced, in line with the green development concept of modern manufacturing.

Taken together, the application of injection molding technology in the manufacturing of Plastic Lighting Lampshade not only brings complex geometric shapes and high-precision manufacturing advantages to the product, but also makes positive contributions in terms of cost-effectiveness and environmental protection. This allows Plastic Lighting Lampshade to gain a competitive advantage in the market and provide consumers with higher quality and more innovative lighting products.

English

English Español

Español 简体中文

简体中文