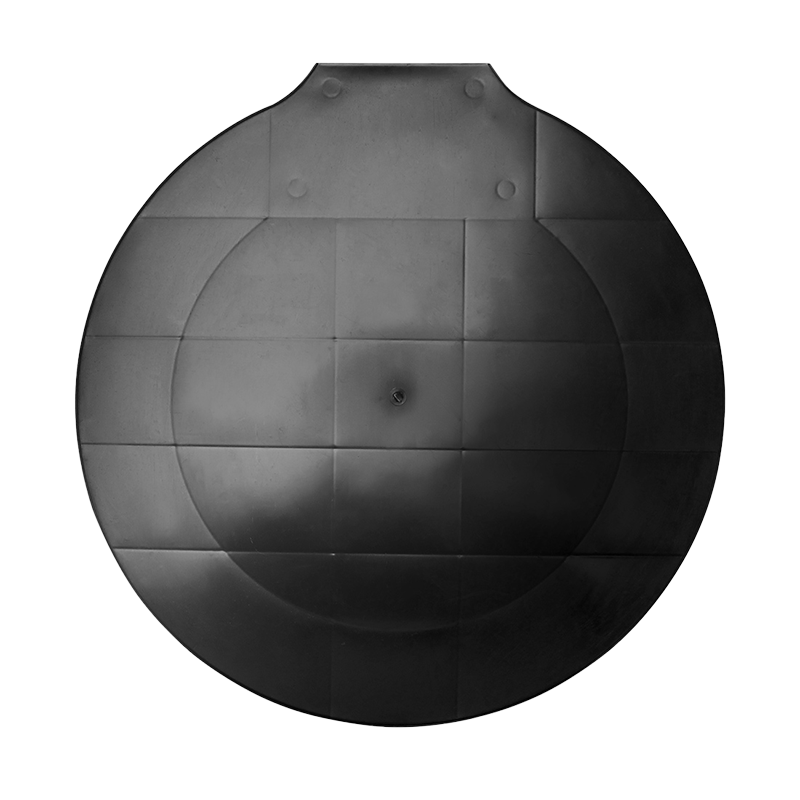

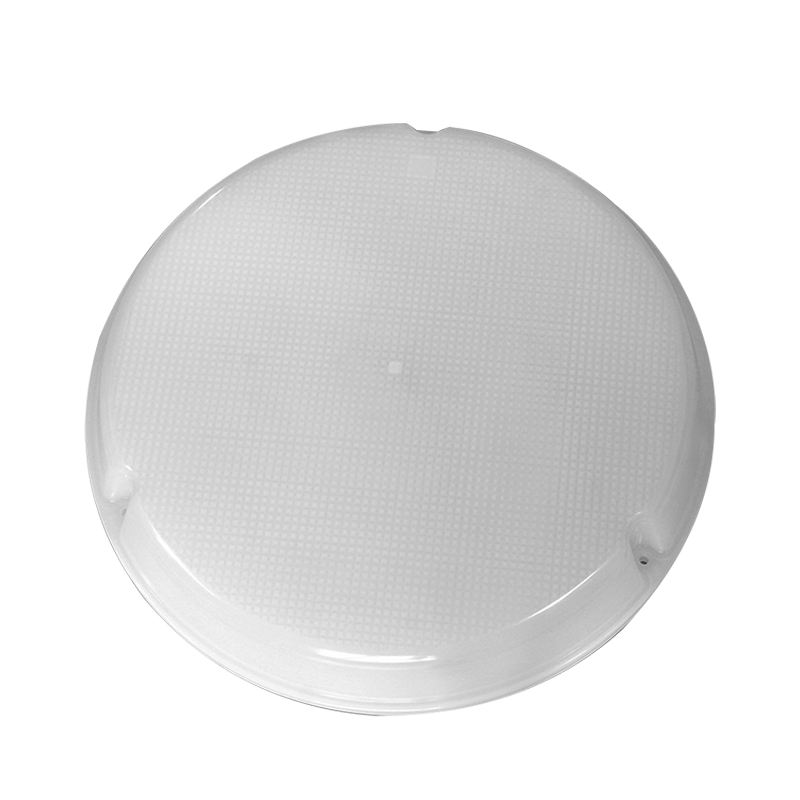

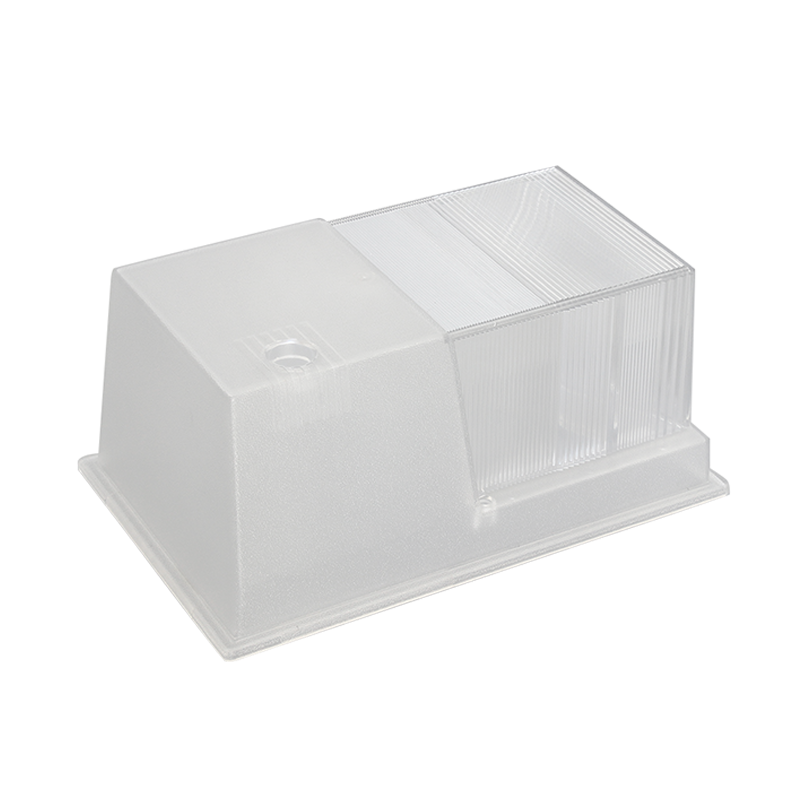

The manufacturing method for plastic car filters has evolved substantially, with injection molding turning into a key aspect in improving performance.

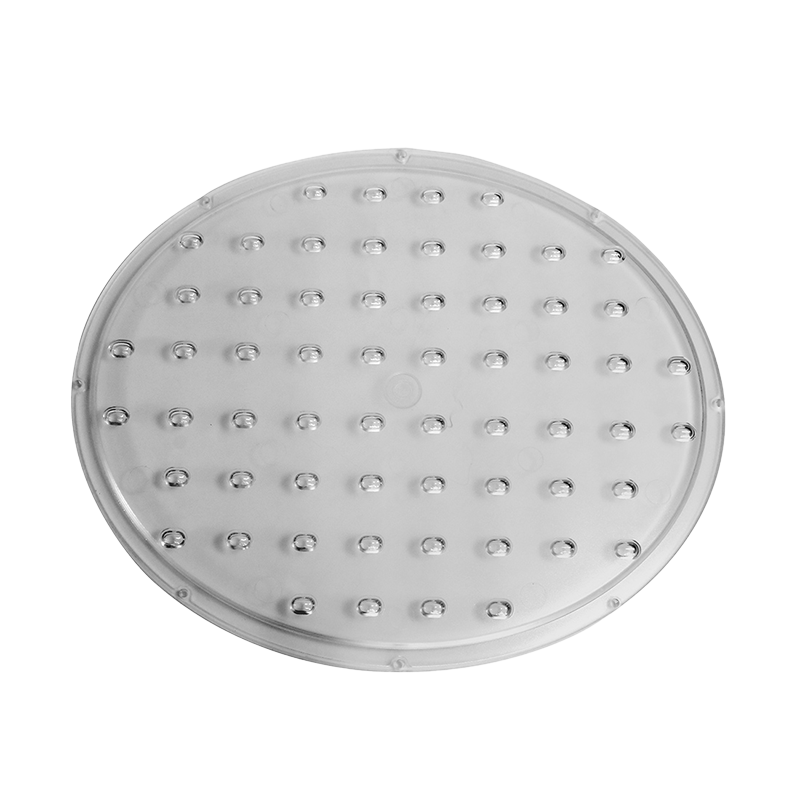

Injection molding can create complicated and precise designs, ensuring that every plastic automotive filter out element meets strict dimensional necessities. The high precision of the process contributes to final product consistency, reduces overall performance variant and improves normal efficiency.

One of the good sized blessings of injection molding is the capability to fast produce plastic car clear out factors. The technique includes injecting molten plastic into a mould hollow space, where rapid cooling and solidification shorten cycle times. This increased productivity is critical to assembly excessive demand situations and optimizing the efficiency of manufacturing operations.

Material performance:

Injection molding uses most effective the amount of plastic had to fill the mould hollow space, minimizing fabric waste. This not most effective contributes to cost-effectiveness however is also steady with sustainable production practices. Efficient material use is essential in the manufacturing of plastic automobile filters, wherein precision and consistency are essential.

The injection molding process affords remarkable design flexibility, permitting complicated shapes and systems to be created in plastic automobile filter out factors. This adaptability ensures producers can optimize designs for maximum filtration efficiency, meet precise overall performance requirements and decorate usual product capability.

Injection molding requires much less physical hard work than conventional production techniques. Automated machinery handles the injection, cooling and ejection procedures, minimizing the danger of errors and growing the overall performance of the production line. Reduced exertions depth manner value savings and extended production output.

Injection molding allows an green high-quality control system. With consistent production and minimum versions, manufacturers can put into effect strict quality inspections at all ranges of manufacturing. This simplification of first-rate manipulate facilitates enhance basic efficiency by way of promptly figuring out and correcting ability issues, making sure that handiest fantastic plastic automotive filters reach the market.

In summary, the injection molding system performs a key function in improving the manufacturing efficiency of plastic car filters. From specific and speedy production to material performance and design flexibility, the advantages of injection molding assist create high-performance clear out elements that meet the demands of modern-day automotive applications. As era keeps to advance, injection molding is probable to stay the cornerstone of the improvement of efficient and sustainable manufacturing processes.

English

English Español

Español 简体中文

简体中文