Industry Knowledge

How is the design of an alarm shell optimized for injection molding, and what factors should be considered

The design of an alarm shell is optimized for injection molding in order to achieve high quality and cost-effective production. Injection molding is a manufacturing process that involves the injection of molten plastic into a mold cavity, which then solidifies to create a final product. The design of an alarm shell is critical for successful injection molding, and there are several factors that should be considered when designing for this manufacturing process.

Firstly, the geometry of the alarm shell should be optimized for injection molding. This means that the design should be drafted to minimize the complexity of the mold cavity, reducing the risk of defects or imperfections in the final product. For example, the shell may be designed with rounded corners or smooth curves to reduce the need for sharp angles or undercuts, which can be difficult to mold without additional complexity. The shell should also be designed with uniform wall thickness, as uneven walls can cause problems such as warping, shrinkage, or inconsistent filling of the mold cavity.

Another important consideration when designing for injection molding is the selection of materials. The material used for the alarm shell should be compatible with the injection molding process and should be able to withstand the high temperatures and pressures involved in the process. Common materials used in injection molding include thermoplastics such as ABS, polycarbonate, and nylon, which have excellent strength, durability, and flexibility. The choice of material should also take into account any specific requirements for the alarm shell, such as resistance to heat, moisture, or impact.

The design of the mold itself is also critical for successful injection molding of an alarm shell. The mold should be designed to accommodate the geometry of the shell and should be made of high-quality materials that can withstand the repeated cycles of heating and cooling during the injection molding process. The mold should also be designed with appropriate gates and runners to allow the molten plastic to flow evenly throughout the mold cavity, ensuring a consistent final product.

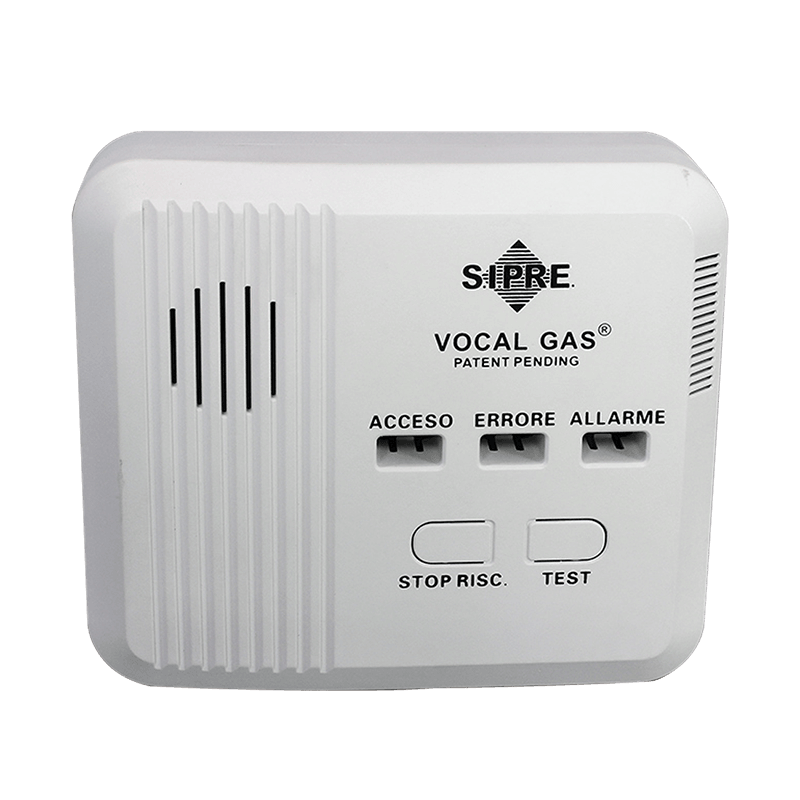

In addition to the technical considerations involved in the design of an alarm shell for injection molding, there are also practical considerations that should be taken into account. For example, the design should be optimized for ease of assembly and disassembly, to allow for efficient production and easy maintenance. The design should also be optimized for aesthetics and functionality, to ensure that the final product meets the desired specifications and is visually appealing to customers.

What are the main advantages and disadvantages of using injection molding for alarm shell production, compared to other manufacturing methods

Injection molding is a manufacturing process that is widely used for producing plastic parts. This process involves melting plastic pellets and injecting them into a mold to create a desired shape. Injection molding is often used for producing alarm shells because of its efficiency and consistency. However, like any manufacturing process, injection molding has its advantages and disadvantages when it comes to producing alarm shells.

One of the main advantages of using injection molding for alarm shell production is its speed and efficiency. Injection molding machines can produce large quantities of parts in a short amount of time, making it a highly efficient process for mass production. Additionally, injection molding allows for precise control of the part dimensions, ensuring that each part is consistent and meets the required specifications.

Another advantage of injection molding is the ability to produce complex geometries. Injection molding allows for the creation of intricate shapes and designs that would be difficult or impossible to achieve with other manufacturing methods. This flexibility is particularly useful in alarm shell production, where unique shapes and designs may be required to accommodate different types of alarms.

Injection molding also produces very little waste compared to other manufacturing methods. Any excess material can be re-melted and reused, reducing material costs and minimizing environmental impact. In addition, the molds used in injection molding are durable and can be reused many times, further reducing waste and cost.

However, injection molding also has some disadvantages when it comes to producing alarm shells. One of the main disadvantages is the high upfront cost of creating the molds. The molds used in injection molding can be expensive to create, especially for complex geometries or unique designs. This cost can be prohibitive for smaller production runs, making injection molding less suitable for smaller-scale manufacturing.

Another disadvantage of injection molding is that it may not be suitable for certain materials. While injection molding is ideal for producing plastic parts, it may not be suitable for materials that require high temperatures or pressure. This limitation can be an issue in alarm shell production, where materials such as metal may be required to meet specific performance requirements.

Finally, injection molding requires a significant amount of energy to operate. This energy usage can be a concern from an environmental perspective, especially if the production process is not optimized for efficiency. However, improvements in technology and energy efficiency are constantly being made, and injection molding can be an eco-friendly option with the right equipment and practices.

What types of plastic materials are commonly used for alarm shell injection molding, and what are their properties

Plastic injection molding is a widely used manufacturing process that involves the injection of molten plastic into a mold to create a specific shape or design. One of the most common applications of injection molding is the production of alarm shells or housings. Alarm shells are typically made of plastic due to the material's lightweight, durability, and ease of customization. There are several types of plastic materials that are commonly used for alarm shell injection molding, each with their unique properties.

One of the most commonly used plastics for alarm shell injection molding is acrylonitrile-butadiene-styrene (ABS). ABS is a thermoplastic polymer that is known for its toughness, impact resistance, and heat resistance. It is also relatively inexpensive, making it a popular choice for injection molding applications. ABS is an opaque material that can be easily colored or painted to match the desired aesthetic of the final product. It is also easily molded, making it suitable for producing complex shapes.

Another commonly used plastic for alarm shell injection molding is polycarbonate (PC). PC is a transparent thermoplastic that is known for its high impact resistance, heat resistance, and optical clarity. It is often used in applications that require high levels of durability and strength, such as electronic devices and automotive parts. PC is also relatively lightweight, making it suitable for producing lightweight alarm shells that are easy to install.

Polypropylene (PP) is another commonly used plastic for alarm shell injection molding. PP is a versatile thermoplastic that is known for its high stiffness, toughness, and chemical resistance. It is also resistant to fatigue and stress cracking, making it suitable for applications that require high levels of durability. PP is often used in automotive, packaging, and medical applications, and it can be easily molded into a variety of shapes.

Another plastic that is commonly used for alarm shell injection molding is polyethylene (PE). PE is a thermoplastic that is known for its flexibility, toughness, and chemical resistance. It is often used in applications that require a high level of resistance to stress cracking, such as pipes, wire insulation, and packaging. PE is also relatively lightweight, making it suitable for producing lightweight alarm shells that are easy to install.

English

English Español

Español 简体中文

简体中文