Industry Knowledge

How has the technology of injection molding for plastic instruments evolved over time

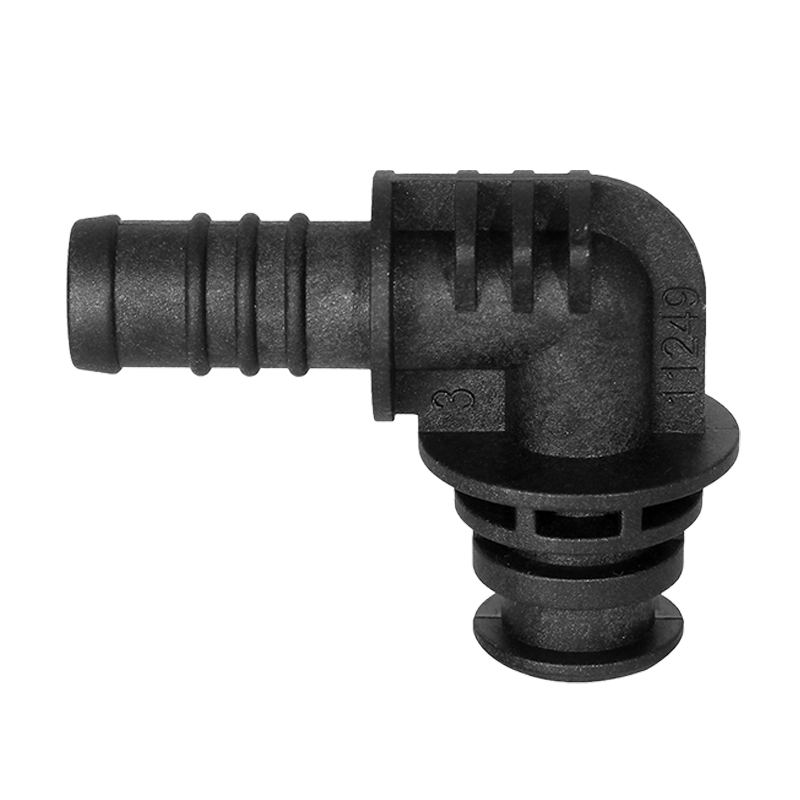

Injection molding is a popular manufacturing process that has been used for decades to produce a wide range of plastic products, including toys, automotive parts, and medical instruments. The technology of injection molding has evolved significantly over time, leading to improvements in efficiency, precision, and overall quality.

The history of injection molding dates back to the late 1800s when the first injection molding machine was developed. At that time, the machines were manually operated, and the process was slow and labor-intensive. The early machines were also limited in terms of the types of materials that could be used and the complexity of the parts that could be produced.

In the 1950s, the first hydraulic injection molding machine was developed, which improved the speed and accuracy of the process. The use of hydraulic pressure allowed for faster cycling times and greater control over the injection and cooling phases. This led to the production of more complex parts and higher volumes of production.

In the 1970s, the introduction of computer-controlled machines marked a significant milestone in the evolution of injection molding technology. These machines used computer programs to precisely control the injection, cooling, and ejection phases, resulting in higher precision and consistency in the production process. The use of computer-aided design (CAD) software also enabled designers to create more complex part geometries, leading to the development of new applications for injection molding.

The 1990s saw the introduction of electric injection molding machines, which provided several advantages over hydraulic machines. Electric machines were quieter, more energy-efficient, and had a smaller footprint, making them ideal for use in smaller manufacturing facilities. They also offered better control over the molding process, resulting in higher quality and consistency.

Today, injection molding technology continues to evolve, driven by advances in materials science, automation, and software. New materials, such as bioplastics and composites, are being developed that offer improved properties and sustainability. Automation and robotics are being integrated into the production process to increase efficiency and reduce labor costs. And advanced software tools are being used to optimize part design and process parameters, resulting in better performance and quality.

One area of particular interest in the development of injection molding technology is the use of micro-injection molding. This involves the production of extremely small parts with high precision, typically used in medical and electronics applications. Micro-injection molding requires specialized equipment and techniques, such as the use of ultra-precise molds and high-speed injection systems.

Another area of focus is the development of multi-material injection molding, which allows for the production of parts with different materials and properties in a single mold. This technology has applications in a wide range of industries, including automotive, aerospace, and consumer electronics.

What is the role of quality control in plastic instrument injection molding

Plastic injection molding is a widely used manufacturing process for creating plastic components and products. One critical aspect of the process is quality control, which plays an essential role in ensuring the final products meet the required standards.

Quality control in plastic injection molding refers to the measures taken to ensure that the products meet the specified requirements. It involves a series of activities that are designed to identify and eliminate defects in the manufacturing process. The primary goal of quality control is to produce consistent, high-quality products that meet customer requirements and expectations.

One of the critical components of quality control in plastic instrument injection molding is process control. Process control involves monitoring the manufacturing process and making adjustments to ensure that the products meet the required specifications. This includes controlling the temperature, pressure, and speed of the injection molding machine. By monitoring and controlling these variables, the manufacturer can produce products that are consistent in terms of quality and performance.

Another important aspect of quality control is product testing. Testing involves subjecting the finished products to various tests to determine their quality and performance. For example, products may be tested for durability, strength, and functionality to ensure that they meet the required standards. The testing process may involve destructive or non-destructive testing, depending on the type of product being produced.

In plastic instrument injection molding, dimensional accuracy is critical, and therefore, dimensional inspections are necessary. A dimensional inspection checks the accuracy of the product’s dimensions, such as thickness, height, and width. This inspection ensures that the products meet the required specifications and tolerances.

Visual inspection is also essential in plastic instrument injection molding. A visual inspection is performed to detect defects that cannot be detected through other inspection methods. Defects such as surface imperfections, color variations, and foreign particles can be detected through visual inspection. A visual inspection ensures that the products are aesthetically pleasing and meet customer expectations.

Another essential aspect of quality control in plastic instrument injection molding is traceability. Traceability involves tracking the materials and processes used in manufacturing the products. This enables manufacturers to identify and eliminate any defects that may occur in the production process. Traceability also helps in identifying the root cause of defects, making it easier to correct the problem and prevent it from occurring in the future.

What are some of the emerging trends in injection molding for plastic instruments

Injection molding is a manufacturing process used to produce a wide variety of plastic instruments, including medical devices, automotive parts, toys, and consumer goods. In recent years, the injection molding industry has seen significant advancements in technology, materials, and processes, leading to emerging trends that are transforming the way plastic instruments are made.

One of the most significant emerging trends in injection molding is the use of additive manufacturing. Additive manufacturing, also known as 3D printing, is a process of creating objects by adding material layer by layer. In injection molding, additive manufacturing is used to create molds with intricate geometries that would be difficult or impossible to achieve using traditional machining methods. This technology enables the production of complex plastic instruments with unique features and shapes, reducing the need for assembly and increasing the overall efficiency of the manufacturing process.

Another emerging trend in injection molding is the use of sustainable materials. Plastic waste has become a global concern, and manufacturers are exploring new ways to reduce their environmental impact. Sustainable materials, such as bioplastics and recycled plastics, are being used to produce plastic instruments. These materials are renewable, biodegradable, and have a lower carbon footprint than traditional plastics. As the demand for sustainable products continues to grow, the use of sustainable materials in injection molding is expected to increase.

Automation is another emerging trend in injection molding. Automation involves the use of robots and other machines to perform tasks that were previously done by human workers. In injection molding, automation can be used to perform tasks such as loading and unloading molds, inspecting parts, and quality control. Automation increases the speed and efficiency of the manufacturing process while reducing the risk of human error. It also enables manufacturers to produce plastic instruments in larger quantities, reducing costs and increasing profitability.

The use of advanced materials is also an emerging trend in injection molding. Advanced materials, such as thermoplastic composites and high-performance polymers, offer improved properties such as strength, stiffness, and temperature resistance. These materials are being used to produce plastic instruments that are lighter, stronger, and more durable than traditional plastics. Advanced materials also enable the production of plastic instruments with new functionalities, such as sensors and conductive properties.

English

English Español

Español 简体中文

简体中文