Industry Knowledge

What are the most popular types of plastic injection molded outdoor lighting parts

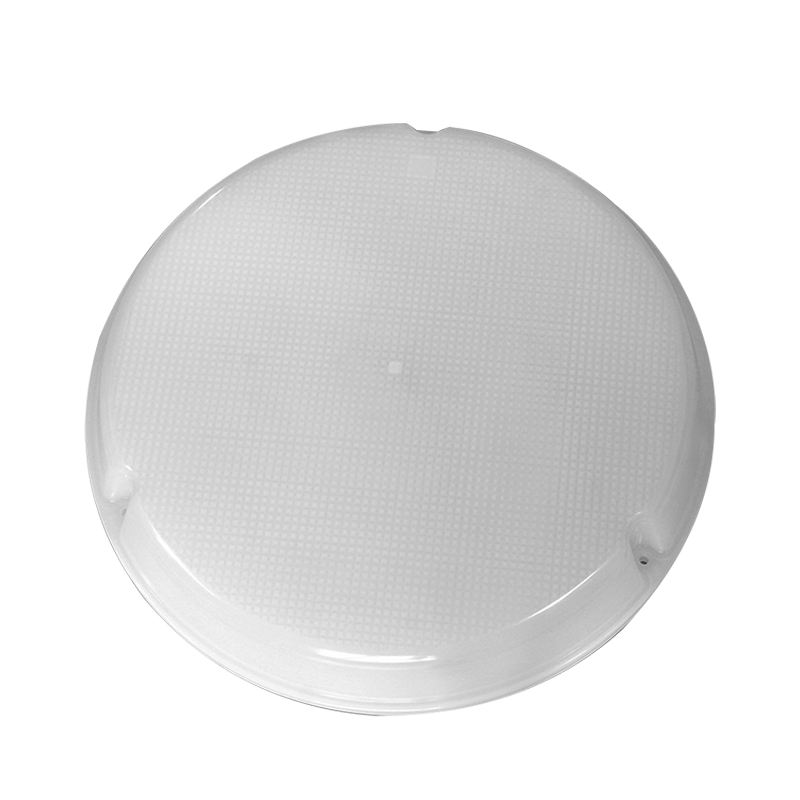

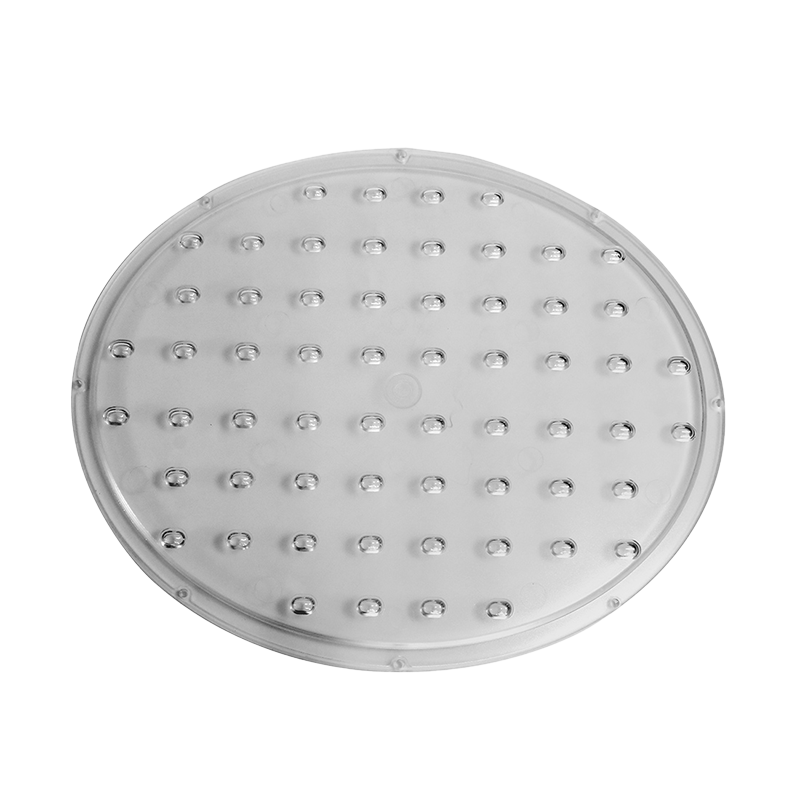

Light diffusers are used to soften the harshness of the light and distribute it evenly. These parts are made from polycarbonate or acrylic material, which is known for its durability and high-impact resistance. Light diffusers can be customized in various shapes and sizes to fit different types of outdoor lighting fixtures.

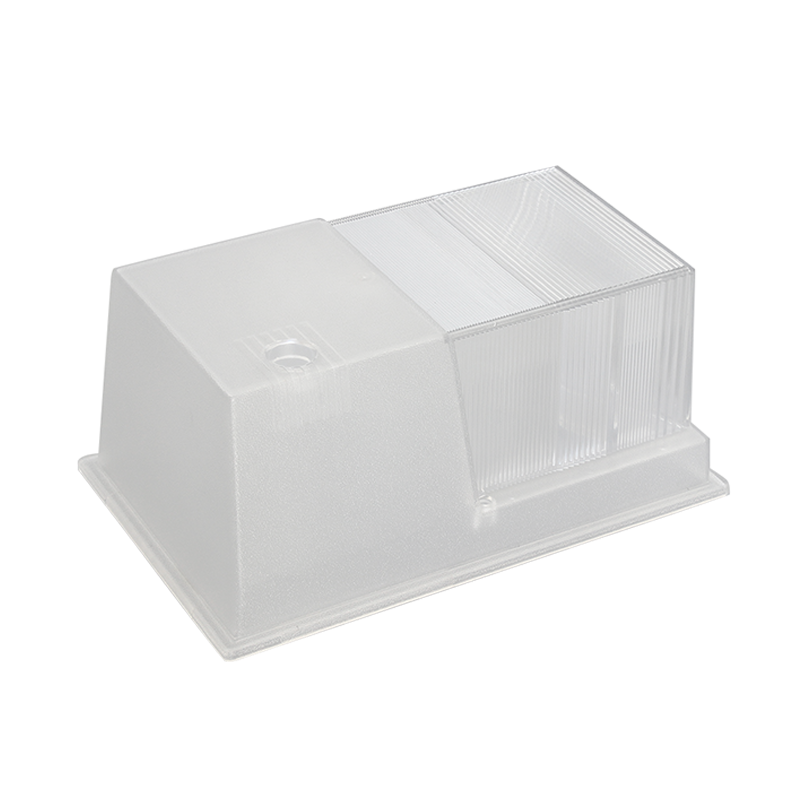

Lens covers are used to protect the light bulbs from dust, dirt, and moisture. These parts are made from materials such as polycarbonate or acrylic, which are known for their high-impact resistance and durability. Lens covers are available in various shapes and sizes to fit different types of outdoor lighting fixtures.

Reflectors are used to direct light in a specific direction, which is important for outdoor lighting fixtures. Reflectors are made from materials such as polycarbonate or acrylic, which are known for their high-reflectivity and durability. Reflectors can be customized in various shapes and sizes to fit different types of outdoor lighting fixtures.

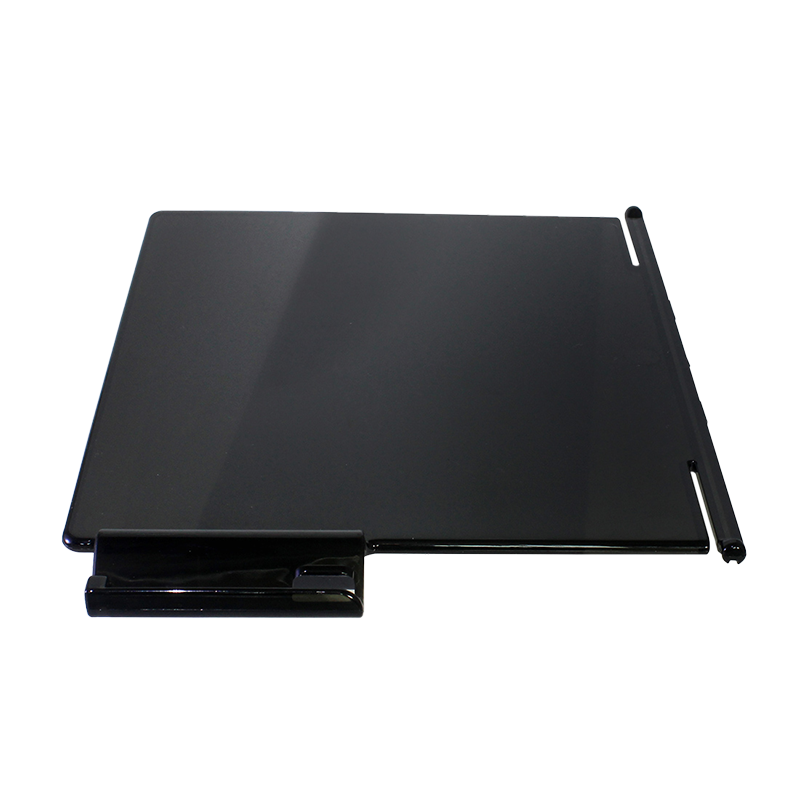

Housing is an essential part of outdoor lighting fixtures, which provides protection to the electrical components of the lighting system. Housing is made from materials such as polycarbonate or ABS, which are known for their high-impact resistance and durability. Housing can be customized in various shapes and sizes to fit different types of outdoor lighting fixtures.

Connectors are used to connect different parts of the outdoor lighting system, such as the housing and the lens cover. Connectors are made from materials such as polycarbonate or nylon, which are known for their high-impact resistance and durability. Connectors can be customized in various shapes and sizes to fit different types of outdoor lighting fixtures.

Mounting brackets are used to mount the outdoor lighting fixture to a wall or pole. Mounting brackets are made from materials such as polycarbonate or aluminum, which are known for their high-impact resistance and durability. Mounting brackets can be customized in various shapes and sizes to fit different types of outdoor lighting fixtures.

How can plastic injection molded outdoor lighting parts be designed to be easily installable and maintainable

Plastic injection molded outdoor lighting parts are an important component of modern urban infrastructure. They provide illumination for sidewalks, parks, and streets, enhancing visibility and safety in public spaces. However, poorly designed lighting fixtures can be difficult to install and maintain, causing unnecessary expenses and downtime.

The first consideration is the ease of installation. The lighting fixtures should be designed to be easily mounted on poles or other structures with minimal effort. The fixtures should come with clear instructions and all the necessary mounting hardware to make the installation process as simple as possible. Additionally, the fixtures should be designed to accommodate a wide range of pole diameters and shapes, ensuring that they can be used in various installation scenarios.

Another important factor is the ease of maintenance. The lighting fixtures should be designed to be easily accessible for maintenance purposes. This means that they should have a simple mechanism for opening and closing, such as a hinged door or removable cover. The internal components, such as the light bulb and wiring, should also be easily accessible for replacement or repair.

In addition to easy access, the fixtures should be designed with durability in mind. The materials used in the injection molding process should be selected for their resistance to weather, UV rays, and other environmental factors that can cause deterioration over time. The components should be designed to be robust and long-lasting, reducing the frequency of maintenance required.

The design of the lighting fixtures should also take into account the need for flexibility. For example, some fixtures may need to be adjusted to different angles or heights to achieve the desired lighting effect. The design should allow for easy adjustment of the fixture without requiring disassembly or the use of specialized tools.

How can plastic injection molded outdoor lighting parts be designed to withstand extreme weather conditions

Plastic injection molded outdoor lighting parts have become increasingly popular due to their affordability and durability. However, one of the biggest challenges for designers is ensuring that these parts can withstand extreme weather conditions, such as high temperatures, heavy rainfall, and extreme cold.

The first strategy that designers can use is to select the right materials for the plastic injection molded parts. Materials such as acrylonitrile butadiene styrene (ABS), polycarbonate, and polypropylene are commonly used for outdoor lighting parts due to their durability and resistance to weathering. These materials can withstand a wide range of temperatures, from extreme heat to freezing temperatures, without losing their structural integrity. Additionally, these materials are resistant to UV radiation, which can cause discoloration and degradation over time.

Another important consideration for designing plastic injection molded outdoor lighting parts is the use of proper design techniques. The design should take into account the expected weather conditions in the location where the lighting will be installed. For example, if the area experiences heavy rainfall, the design should ensure that water will not be able to penetrate the electrical components, which can cause damage or pose a safety risk. The design should also include features such as vents and drainage holes to prevent moisture buildup, which can lead to corrosion and electrical failures.

In addition to material selection and proper design techniques, the manufacturing process also plays a crucial role in ensuring that plastic injection molded outdoor lighting parts are able to withstand extreme weather conditions. The injection molding process should be carefully controlled to ensure that the plastic parts are free from defects, such as voids or air bubbles, which can weaken the structure of the part. The use of additives, such as UV stabilizers and flame retardants, can also improve the durability and performance of the plastic parts.

What are the key design considerations for plastic injection molded outdoor lighting parts

Plastic injection molding is a popular manufacturing process used to produce a wide range of products, including outdoor lighting parts. However, designing outdoor lighting parts for plastic injection molding requires special considerations to ensure that the final product meets the requirements for durability, functionality, and aesthetic appeal.

The choice of material is a critical design consideration for plastic injection molded outdoor lighting parts. Outdoor lighting parts are exposed to harsh weather conditions, such as rain, wind, and sun. Therefore, the material used must be able to withstand these conditions without degrading or becoming brittle. Common materials used for outdoor lighting parts include polycarbonate, acrylonitrile butadiene styrene (ABS), and polypropylene. Each material has its own unique properties and should be chosen based on the specific needs of the product.

The geometry and design of the part can greatly impact the success of plastic injection molding. It is important to design the part with moldability in mind. Simple part designs with minimal undercuts, sharp corners, and thin walls are easier to mold and reduce the risk of defects. Additionally, proper draft angles should be incorporated to ensure that the part can be easily ejected from the mold. It is also important to consider the final assembly of the part and design it with features that allow for easy assembly.

Outdoor lighting parts require a surface finish that can withstand harsh environmental conditions. For example, textured finishes are often used to prevent the accumulation of dirt and grime. It is also important to consider the aesthetics of the product and choose a surface finish that enhances the overall appearance of the part.

Color and pigmentation are important design considerations for plastic injection molded outdoor lighting parts. Outdoor lighting parts must be able to withstand fading and discoloration caused by exposure to sunlight. It is important to choose a material and color that are UV resistant to prevent discoloration over time. Pigments can also be added to enhance the color and visual appeal of the product.

The wall thickness of the part is an important design consideration for plastic injection molding. The thickness of the walls impacts the strength and durability of the part. Thicker walls can provide additional strength and rigidity, but can also increase the likelihood of sink marks and warping. It is important to balance the wall thickness to ensure that the part is strong enough to withstand outdoor conditions while also being moldable.

English

English Español

Español 简体中文

简体中文