Industry Knowledge

What materials are commonly used in plastic sensor shell injection molding

Injection molding is one of the most common methods used to manufacture plastic parts, including sensor shells for electronic components. It is a process that involves injecting molten plastic material into a mold cavity under high pressure and then cooling the material to form a solid object. The choice of plastic material used for injection molding is critical to the quality and functionality of the sensor shell.

Acrylonitrile Butadiene Styrene (ABS) ABS is a thermoplastic polymer that is commonly used in injection molding due to its high strength, impact resistance, and ability to be molded into complex shapes. ABS also has good dimensional stability, which makes it an ideal material for sensor shells that require precise measurements. Additionally, ABS is a relatively low-cost material, making it an attractive option for mass production.

Polycarbonate (PC) Polycarbonate is another popular plastic material used in injection molding, especially for applications that require high impact resistance and clarity. It is a transparent thermoplastic that has excellent dimensional stability, making it ideal for use in sensor shells that require tight tolerances. Polycarbonate is also resistant to UV light and has good electrical insulation properties.

Polypropylene (PP) Polypropylene is a versatile thermoplastic polymer that is commonly used in injection molding due to its low cost, high chemical resistance, and excellent mechanical properties. PP is also lightweight, making it an ideal material for sensor shells that require portability. It is resistant to moisture, making it a great choice for applications that require water resistance.

Polyethylene (PE) Polyethylene is a low-cost thermoplastic polymer that is commonly used in injection molding for sensor shells that require flexibility and durability. PE is lightweight, making it ideal for use in portable sensors, and has excellent chemical resistance, making it resistant to corrosion and other types of damage.

Polystyrene (PS) Polystyrene is a versatile thermoplastic polymer that is commonly used in injection molding due to its low cost and excellent clarity. PS is also lightweight and has excellent electrical insulation properties, making it ideal for sensor shells that require transparency and electrical conductivity.

What are some of the key trends in plastic sensor shell injection molding technology

Plastic sensor shell injection molding technology is a crucial process in the manufacture of plastic parts for a variety of industries. As technology continues to advance, there are several key trends that are shaping the plastic sensor shell injection molding process.

One of the primary trends in plastic sensor shell injection molding technology is the move towards more sustainable materials. The use of sustainable materials in injection molding has become increasingly important as the global community seeks to reduce plastic waste and pollution. This trend has led to the development of biodegradable plastics and other sustainable materials, which can be used in injection molding. The use of sustainable materials in injection molding not only helps to reduce plastic waste but also reduces the environmental impact of the manufacturing process.

Another trend in plastic sensor shell injection molding technology is the use of automation and robotics in the manufacturing process. Automation has been widely adopted in various industries as it helps to improve efficiency, reduce labor costs and improve product quality. In injection molding, automation and robotics are used to streamline the manufacturing process, reduce waste, and improve the consistency of the final product. Robots can be used to perform tasks such as loading and unloading parts, as well as quality control inspections.

Advanced software and simulation tools are also playing an increasingly important role in plastic sensor shell injection molding technology. These tools can be used to model and simulate the injection molding process, allowing manufacturers to optimize their processes for maximum efficiency and product quality. Simulation tools can also be used to identify potential defects or problems before they occur, allowing for preemptive measures to be taken. This can help to reduce waste and improve product quality.

Another trend in plastic sensor shell injection molding technology is the use of multi-material molding. Multi-material molding allows for the creation of parts with multiple materials, which can be used to improve product functionality or aesthetics. For example, a part may require a hard plastic shell for durability, but also require a soft rubberized grip for comfort. Multi-material molding allows for the creation of parts with both hard and soft materials, without the need for assembly or additional manufacturing steps.

How is plastic sensor shell injection molding different from other types of injection molding

Injection molding is a popular manufacturing process that has revolutionized the way plastic products are made. It is a cost-effective method that can produce large quantities of products with high accuracy and consistency. There are various types of injection molding, and each type is used to create different products.

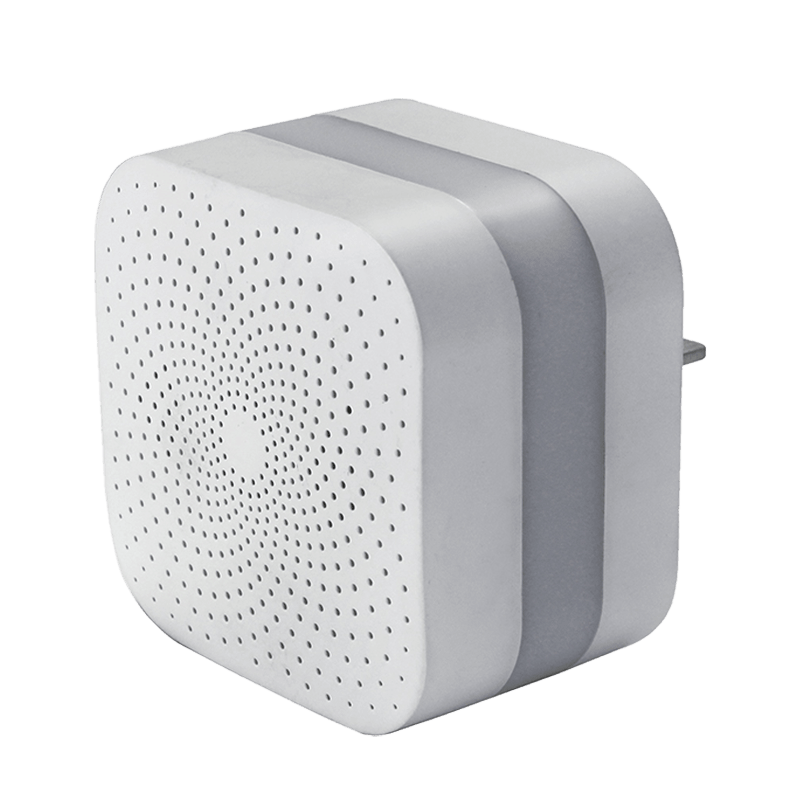

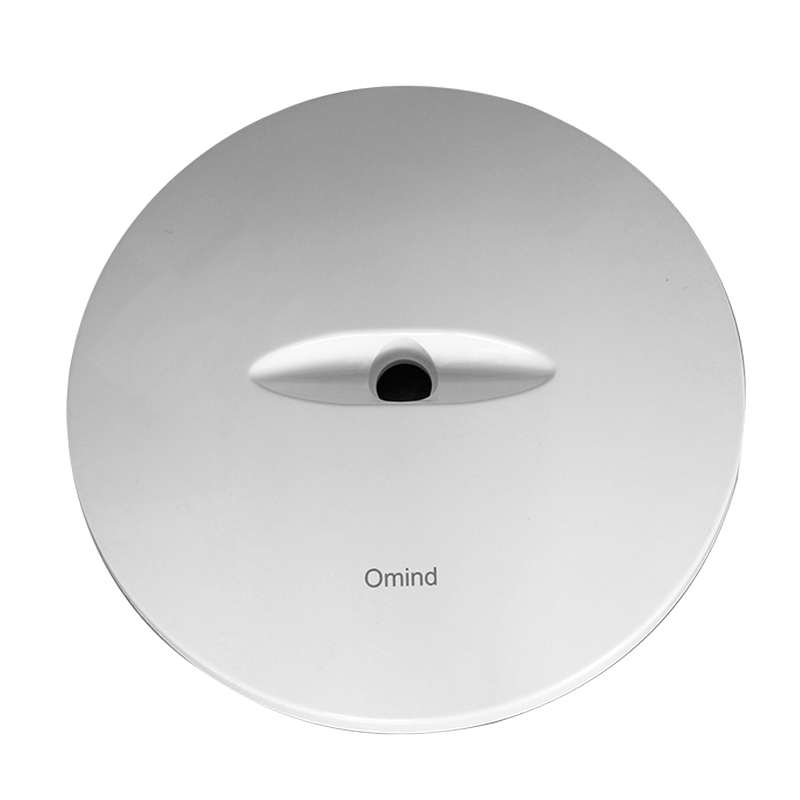

Plastic sensor shell injection molding is a type of injection molding that is used to create sensor shells. A sensor shell is a protective covering that houses electronic components that detect and respond to changes in the environment. They are widely used in various industries, such as automotive, aerospace, and medical.

The plastic sensor shell injection molding process is similar to other types of injection molding. It involves melting plastic pellets and injecting the molten plastic into a mold cavity. The molten plastic then solidifies, and the mold opens to release the finished product.

Precision and accuracy: Plastic sensor shells require a high level of precision and accuracy because they need to fit tightly around the electronic components. Any deviation in size or shape can cause the sensor to malfunction. Therefore, the molds used in plastic sensor shell injection molding are designed with high precision to ensure that the final product meets the required specifications.

Material selection: The material used for plastic sensor shell injection molding is different from other types of injection molding. Sensor shells are typically made from engineering plastics, such as polycarbonate, nylon, and acrylonitrile-butadiene-styrene (ABS). These materials have high strength, durability, and resistance to impact, heat, and chemicals.

Surface finish: The surface finish of plastic sensor shells is crucial because it affects the performance of the sensor. A rough or uneven surface can interfere with the sensor's ability to detect changes in the environment. Therefore, the molds used in plastic sensor shell injection molding are designed to create a smooth surface finish.

Part design: The design of plastic sensor shells is different from other types of injection molding because they need to fit around the electronic components. The mold design needs to take into account the shape and size of the components and ensure that the sensor shell fits tightly around them.

Quality control: Plastic sensor shell injection molding requires strict quality control measures to ensure that the final product meets the required specifications. The molds are regularly inspected for wear and tear, and the finished products are inspected for defects, such as warping, cracking, or incomplete filling.

English

English Español

Español 简体中文

简体中文