Industry Knowledge

How does the injection molding process for plastic auto filter elements differ from other injection molding processes

Injection molding is one of the most widely used manufacturing processes for producing plastic components. This process involves injecting molten plastic into a mold cavity and allowing it to cool and solidify into the desired shape. The process is used in a wide range of industries, including automotive, medical, consumer goods, and more.

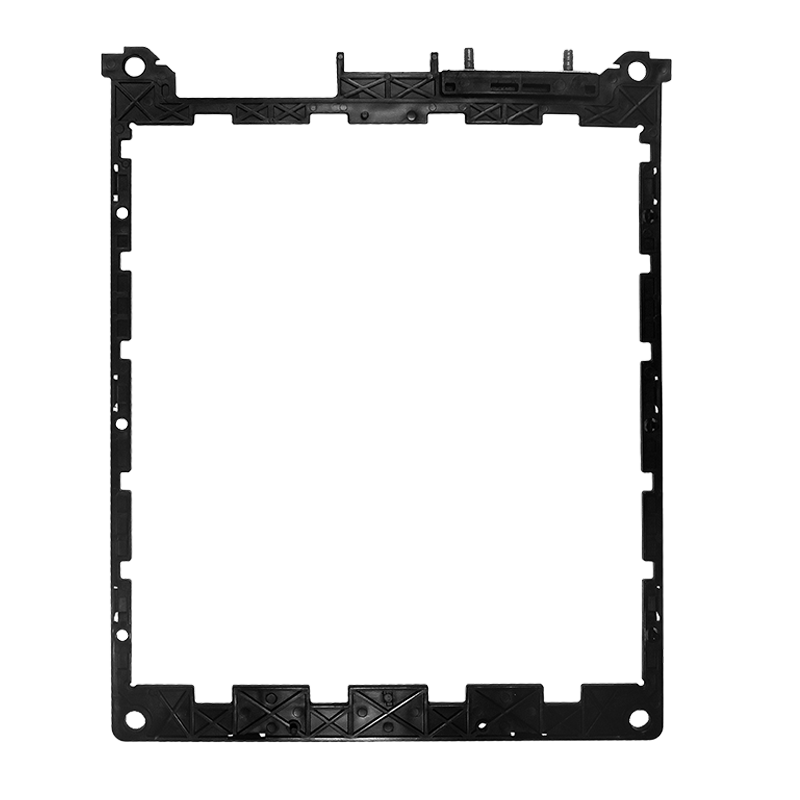

In the automotive industry, injection molding is commonly used to produce plastic components for various parts, including auto filter elements. These elements are used to filter the air and oil in a vehicle's engine, preventing contaminants from causing damage to the engine. The injection molding process for plastic auto filter elements differs from other injection molding processes in several ways.

The first difference is the material used for the filter elements. Plastic auto filter elements are typically made from a thermoplastic elastomer, which is a type of polymer that has both thermoplastic and elastomeric properties. This material is chosen for its ability to withstand high temperatures and pressures, as well as its resistance to chemicals and oils. Other injection molding processes may use different materials, depending on the application.

The second difference is the design of the mold. The mold for plastic auto filter elements is designed with intricate features that allow for the filtration of particles and contaminants from the engine's oil and air. This requires a high level of precision in the mold design and manufacturing process. Other injection molding processes may not require the same level of precision in the mold design.

The third difference is the molding process itself. The injection molding process for plastic auto filter elements typically involves high pressure and high temperature to ensure the material flows into all the intricate features of the mold. The mold may also need to be heated to maintain the desired temperature of the material during the molding process. Other injection molding processes may use different parameters, depending on the material and the design of the part.

The fourth difference is the post-processing steps. Plastic auto filter elements often require additional processing steps after molding to ensure they meet the desired specifications. This may include trimming, cleaning, and testing to ensure the filters meet the required filtration efficiency and durability. Other injection molding processes may not require the same level of post-processing.

Finally, the injection molding process for plastic auto filter elements may require specialized equipment and expertise. This is because of the high precision required in the mold design, molding process, and post-processing steps. This may include specialized molding machines, mold making equipment, and quality control equipment. Other injection molding processes may not require the same level of specialized equipment and expertise.

What types of plastic materials are commonly used in the injection molding of auto filter elements

Thermoplastic elastomers (TPE): Thermoplastic elastomers (TPE) are a popular choice for auto filter elements because of their unique properties. TPEs combine the characteristics of thermoplastics and elastomers, making them flexible, durable, and resistant to chemicals and heat. They can be easily molded into complex shapes, making them an excellent choice for intricate designs in auto filter elements. TPEs are also recyclable, making them an environmentally friendly option.

Polypropylene (PP): Polypropylene (PP) is another commonly used material in the injection molding of auto filter elements. PP is a thermoplastic polymer that is strong, lightweight, and resistant to heat and chemicals. It has excellent mechanical properties, making it suitable for demanding applications such as auto filter elements. PP is also cost-effective and can be easily recycled, making it an environmentally friendly option.

Acrylonitrile Butadiene Styrene (ABS): Acrylonitrile Butadiene Styrene (ABS) is a popular plastic material that is commonly used in a wide range of applications, including auto filter elements. ABS is known for its excellent toughness, impact resistance, and chemical resistance. It can be easily molded into complex shapes and has a high degree of dimensional stability. ABS is also recyclable, making it an environmentally friendly option.

Polyamide (PA): Polyamide (PA), also known as nylon, is a strong and durable plastic material that is commonly used in the injection molding of auto filter elements. PA has excellent mechanical properties, making it suitable for demanding applications. It is also resistant to heat, chemicals, and abrasion, making it an excellent choice for auto filter elements. PA is also recyclable, making it an environmentally friendly option.

Polyphenylene Oxide (PPO): Polyphenylene Oxide (PPO) is a high-performance thermoplastic polymer that is commonly used in the injection molding of auto filter elements. PPO is known for its high heat resistance, mechanical strength, and dimensional stability. It is also resistant to chemicals, making it an excellent choice for demanding applications such as auto filter elements.

Plastic auto filter elements are a critical component in the automotive industry, and their manufacturing process plays a vital role in ensuring their reliability and functionality. Injection molding is a popular manufacturing process for plastic auto filter elements, and it offers several advantages over other manufacturing processes.

Injection molding is a cost-effective manufacturing process for producing plastic auto filter elements. The initial tooling costs can be high, but the per-unit cost is low when producing high volumes of parts. Injection molding also allows for the production of complex geometries, which reduces the need for additional assembly and reduces overall manufacturing costs.

Injection molding can produce plastic auto filter elements at high production rates. The process involves injecting molten plastic into a mold cavity, allowing it to cool and solidify, and then removing the finished part from the mold. This cycle time is fast, and with the use of multiple cavities in the mold, multiple parts can be produced simultaneously, increasing the production rate.

Injection molding provides consistent quality in the production of plastic auto filter elements. The process is highly repeatable and produces parts with consistent dimensions and properties. The use of computer-controlled machines ensures accurate and consistent production, and the use of high-quality materials and molds ensures that the parts meet the required specifications.

Injection molding provides design flexibility in the production of plastic auto filter elements. The process allows for the production of complex geometries, which can be difficult or impossible to produce with other manufacturing processes. Injection molding also allows for the integration of multiple components into a single part, reducing the need for additional assembly.

Injection molding offers a wide range of material selection for the production of plastic auto filter elements. The choice of material can be tailored to meet the required specifications for the application. Different materials have varying properties and characteristics that can affect the final product, and injection molding allows for the use of various materials to achieve the desired properties.

Injection molding is an environmentally friendly manufacturing process for producing plastic auto filter elements. The process generates minimal waste, and the materials used can be recycled, reducing the environmental impact. The production of plastic auto filter elements through injection molding also results in parts that are lightweight, reducing the fuel consumption of the vehicle.

English

English Español

Español 简体中文

简体中文