Industry Knowledge

What are the advantages of using commodity plastic mold parts in the manufacturing industry

Plastic injection molding is a popular manufacturing process that involves creating complex and detailed parts by injecting melted plastic material into a mold cavity. In the plastic injection molding process, the mold is a crucial component that determines the quality, accuracy, and consistency of the final product. The mold is made up of several parts, including core pins, ejector pins, inserts, and slide cores, among others. The choice of materials for these mold parts is critical as it directly affects the quality and cost of the finished product. In recent years, commodity plastic mold parts have become increasingly popular in the manufacturing industry due to their numerous advantages.

The first advantage of using commodity plastic mold parts is cost-effectiveness. Commodity plastic materials are readily available and less expensive compared to other high-performance materials used in molding applications. They are made from commonly used polymers such as polystyrene, polyethylene, and polypropylene, among others, which are widely produced and readily available. This makes commodity plastic mold parts a cost-effective alternative to expensive, high-performance materials that are used in specialized applications. Manufacturers can save money by using commodity plastic mold parts, especially in high-volume production runs where costs can quickly add up.

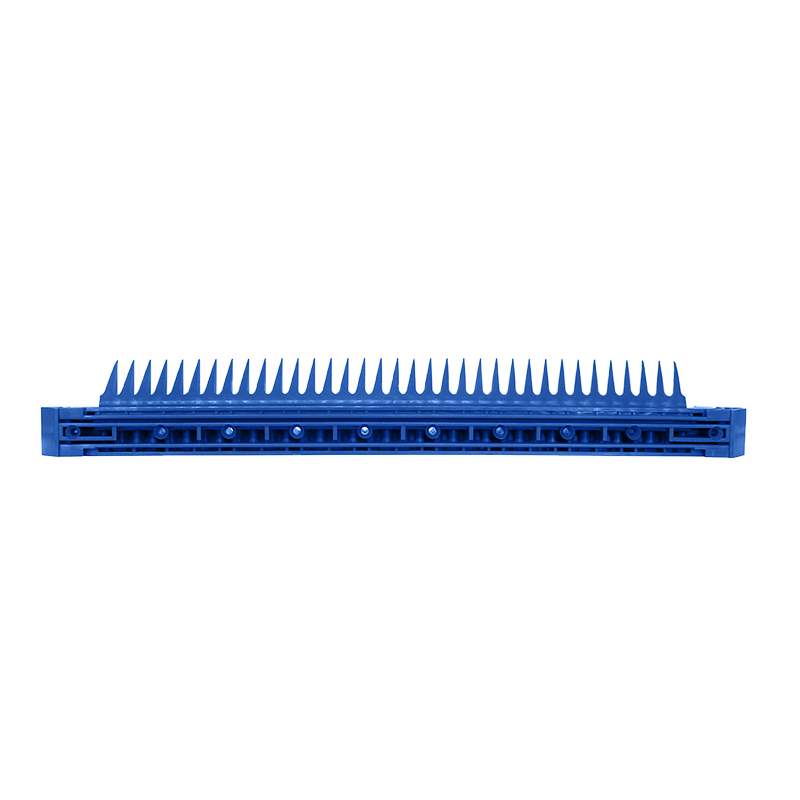

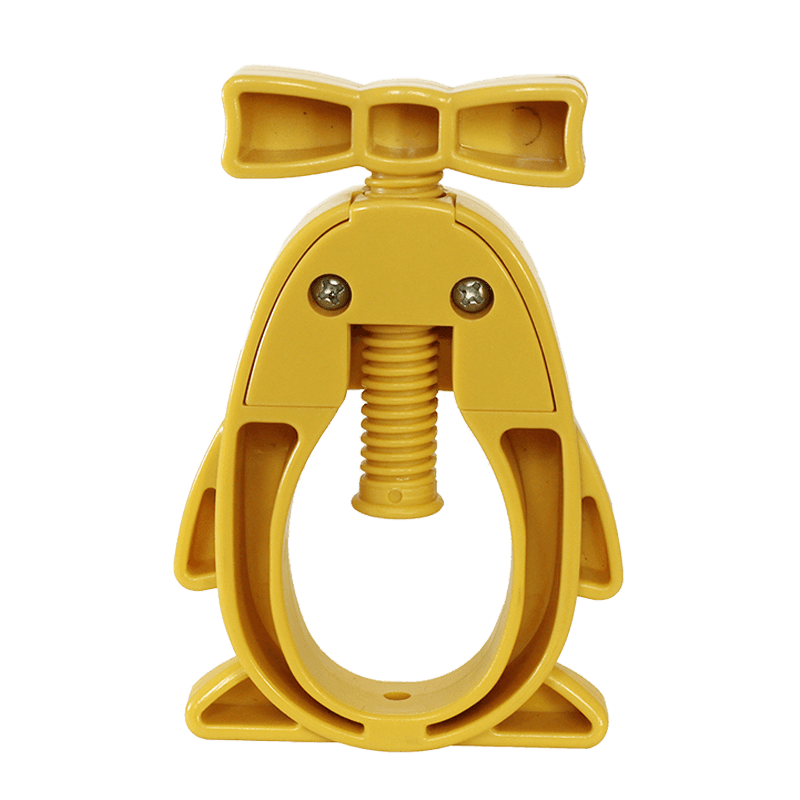

The second advantage of using commodity plastic mold parts is versatility. Commodity plastics can be used to produce a wide range of products, from simple and low-cost items to complex and high-precision parts. They offer a broad range of physical and mechanical properties that can be tailored to suit specific manufacturing requirements. Commodity plastic mold parts are also available in different shapes, sizes, and colors, making them suitable for a wide range of applications. This versatility is particularly useful in the manufacturing industry, where there is a need for parts that can be customized to meet the unique requirements of different products.

The third advantage of using commodity plastic mold parts is durability. Commodity plastics are known for their toughness and durability, making them ideal for use in high-stress applications. They can withstand high temperatures, pressure, and wear, which makes them suitable for use in demanding manufacturing environments. This durability also ensures that the mold parts have a longer lifespan, reducing the need for frequent replacements and repairs. This results in cost savings for manufacturers and increases productivity.

The fourth advantage of using commodity plastic mold parts is ease of use. Commodity plastic materials are easy to work with and require less expertise and specialized equipment compared to other high-performance materials. This ease of use makes it possible for manufacturers to produce high-quality parts quickly and efficiently, reducing production time and costs. Additionally, commodity plastic mold parts can be easily replaced or repaired, which minimizes downtime and increases productivity.

The fifth advantage of using commodity plastic mold parts is environmental friendliness. Commodity plastics are recyclable, which makes them an environmentally friendly option for manufacturers. Recycling helps to reduce waste and conserve resources, making it an essential component of sustainable manufacturing practices. By using commodity plastic mold parts, manufacturers can contribute to environmental conservation efforts while also enjoying the benefits of cost savings and increased productivity.

What are the most common types of commodity plastic mold parts used in various industries

Sprue bushings are essential components of the plastic injection molding process. They are used to direct molten plastic from the nozzle of the injection molding machine into the mold cavity. Sprue bushings are typically made of stainless steel or brass and are available in various sizes and configurations to accommodate different injection molding machines and molds.

Ejector pins are used to push the finished product out of the mold after the plastic has cooled and solidified. They are usually made of hardened steel and come in different diameters and lengths. Ejector pins can be straight, stepped, or angled to match the shape of the mold cavity.

Core pins are used to create internal features or holes in the molded product. They are typically made of hardened steel and come in various shapes and sizes, depending on the requirements of the product design. Core pins are often used in conjunction with other mold components, such as slide cores, to create complex shapes and features.

Guide pins and bushings are used to align the mold halves and maintain proper spacing during the injection molding process. They are typically made of hardened steel and come in various sizes and shapes, depending on the mold design. Guide pins and bushings are critical components of the injection molding process, as misalignment can cause defects in the finished product.

Hot runner systems are used to maintain a consistent temperature in the mold cavity during the injection molding process. They consist of a heated manifold, nozzles, and a temperature controller. Hot runner systems are commonly used in high-volume injection molding applications and can reduce waste and cycle times compared to cold runner systems.

Cooling systems are used to rapidly cool the molten plastic as it enters the mold cavity to ensure proper solidification and prevent warping or distortion. Cooling systems can be built into the mold or added as an external component. They can be water-cooled or air-cooled, depending on the requirements of the product design.

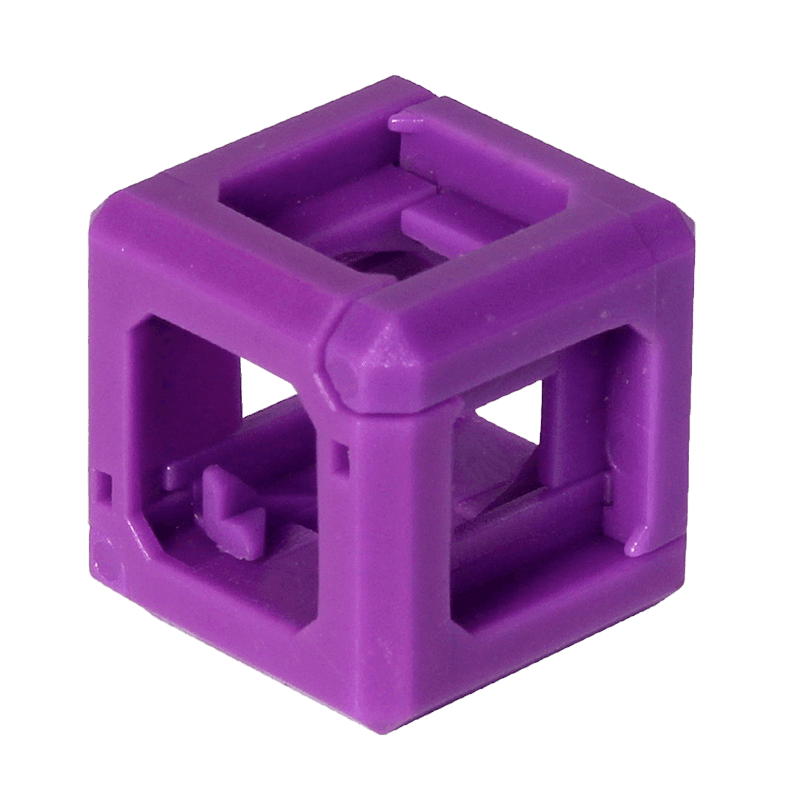

Mold bases are the foundation of the injection mold and provide support for all the other mold components. They are typically made of steel and come in various sizes and configurations, depending on the size and complexity of the product design. Mold bases are critical components of the injection molding process, as they provide the stability and rigidity necessary for precise molding.

How do commodity plastic mold parts compare to other types of mold parts in terms of cost and performance

Commodity plastic mold parts are widely used in the manufacturing industry due to their low cost and versatility. They are commonly used to create simple, mass-produced products such as food containers, disposable cutlery, and toys. However, they are also used in more complex products such as automotive components and medical devices.

One of the main advantages of commodity plastic mold parts is their low cost. These parts are made from thermoplastic materials that are readily available and easy to process. They can be produced using injection molding, a high-volume manufacturing process that allows for the production of large quantities of parts at a low cost. Commodity plastic mold parts are typically made from materials such as polypropylene (PP), polystyrene (PS), and polyethylene (PE). These materials are inexpensive and have a low scrap rate, which further reduces the overall cost of production.

On the other hand, specialized mold parts are made from materials that are more expensive and harder to process. These materials include engineering plastics such as nylon, acetal, and polycarbonate. They also include metal alloys such as aluminum and steel. These materials are more expensive than commodity plastics and require more sophisticated manufacturing processes, which drive up the cost of production.

Commodity plastic mold parts are suitable for simple products that require low strength and durability. These parts are lightweight and have good dimensional stability, which makes them ideal for applications where precision is important. However, they are not suitable for products that require high strength or durability, as they are prone to cracking and breaking under stress. In addition, commodity plastic mold parts have poor resistance to chemicals and UV light, which limits their use in applications where these factors are important.

Specialized mold parts, on the other hand, are designed for applications that require high strength and durability. These parts are made from materials that are engineered to withstand extreme conditions, such as high temperatures, corrosive chemicals, and UV light. For example, nylon is used to make gears and bearings that require high strength and wear resistance. Polycarbonate is used to make safety goggles and face shields that require high impact resistance. Aluminum and steel are used to make molds for high-volume production runs.

What factors should be considered when selecting commodity plastic mold parts for a specific application

Plastic molds are a crucial component of many industries, including manufacturing, packaging, and consumer goods. Selecting the right commodity plastic mold parts for a specific application can make a significant difference in the final product's quality, cost-effectiveness, and production efficiency.

Firstly, the type of plastic material used in the mold is a crucial consideration. The plastic material used in the mold must be compatible with the plastic used in the final product. For example, if the final product is made of high-density polyethylene (HDPE), the mold must also be made of HDPE or a material that is compatible with HDPE. Choosing a material that is not compatible with the final product can result in poor product quality, damage to the mold, and increased production costs.

Secondly, the design of the mold is an important factor to consider. The mold must be designed to meet the specific requirements of the product, such as shape, size, and texture. The mold design should also take into consideration the production process, including the injection molding process, cooling time, and ejection process. The mold's design should be optimized for the specific application, ensuring that the final product meets the required quality standards.

Thirdly, the selection of mold components is another essential factor to consider. The selection of mold components, such as mold bases, cores, cavities, and ejectors, can affect the final product's quality, production efficiency, and cost. For example, selecting a mold base with poor thermal conductivity can result in longer cooling times, which can increase production costs. On the other hand, selecting high-quality ejectors can improve the ejection process and reduce the risk of product damage.

Fourthly, the manufacturing process used to produce the mold parts is a crucial factor to consider. The manufacturing process can affect the quality, accuracy, and durability of the mold parts. For example, molds produced using CNC machining can offer high precision and accuracy, while molds produced using 3D printing may not be as precise or durable. Choosing a manufacturing process that meets the specific requirements of the application can result in better product quality, reduced production costs, and improved production efficiency.

English

English Español

Español 简体中文

简体中文