Robot dogs, or "robo-dogs," have been around for several decades. They were initially simple and crude, often consisting of basic mechanical movements and limited interactivity. However, as technology has advanced, these robotic pets have become remarkably realistic, emulating the appearance, movements, and even the behavior of real dogs. Today, some robot dogs can perform tricks, respond to voice commands, and even express emotions through sophisticated artificial intelligence.

One of the critical drivers behind this evolution has been the adoption of injection molding in the manufacturing process.

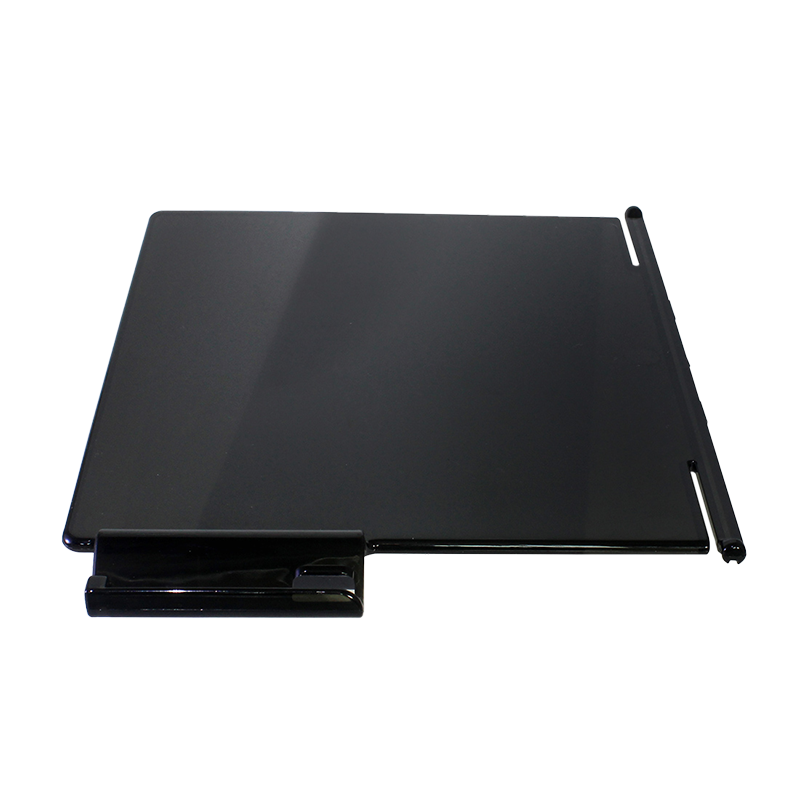

Injection molding is a manufacturing process that involves injecting molten material into a mold to produce a wide range of plastic and metal parts. This technique offers several benefits that have been instrumental in improving the quality and functionality of robot dogs:

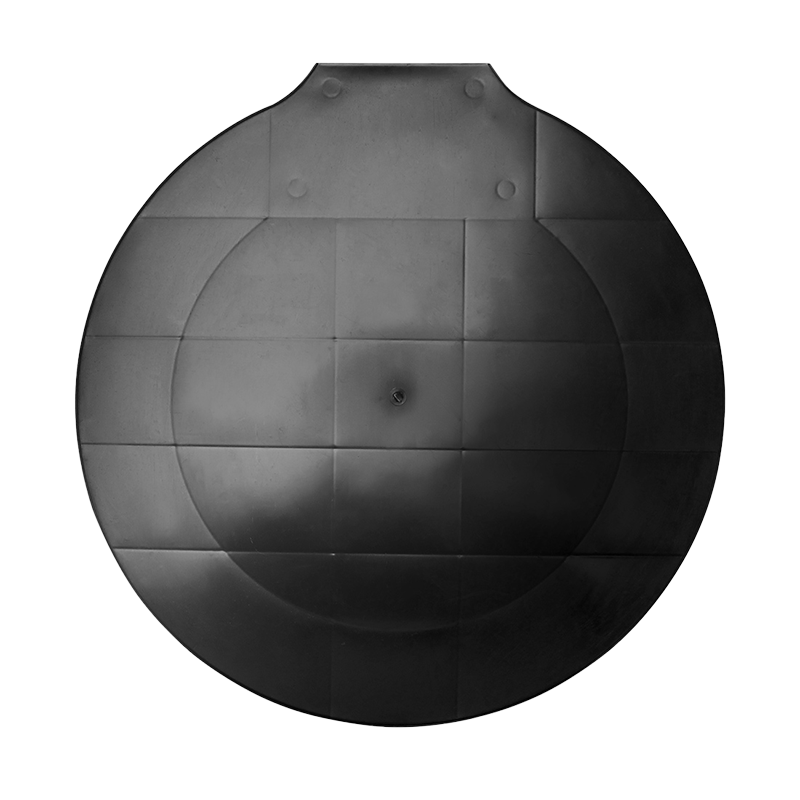

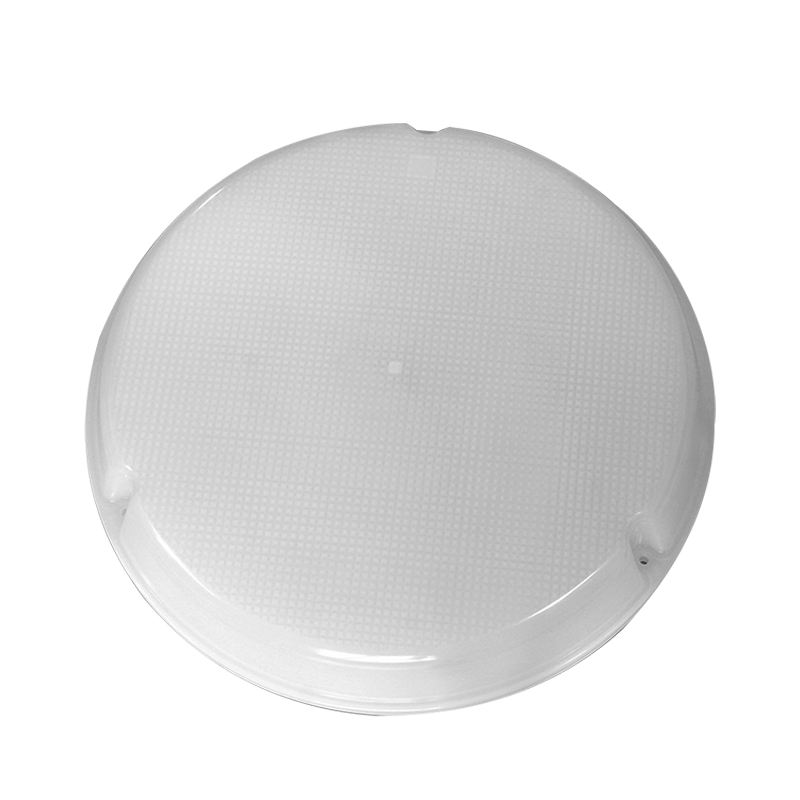

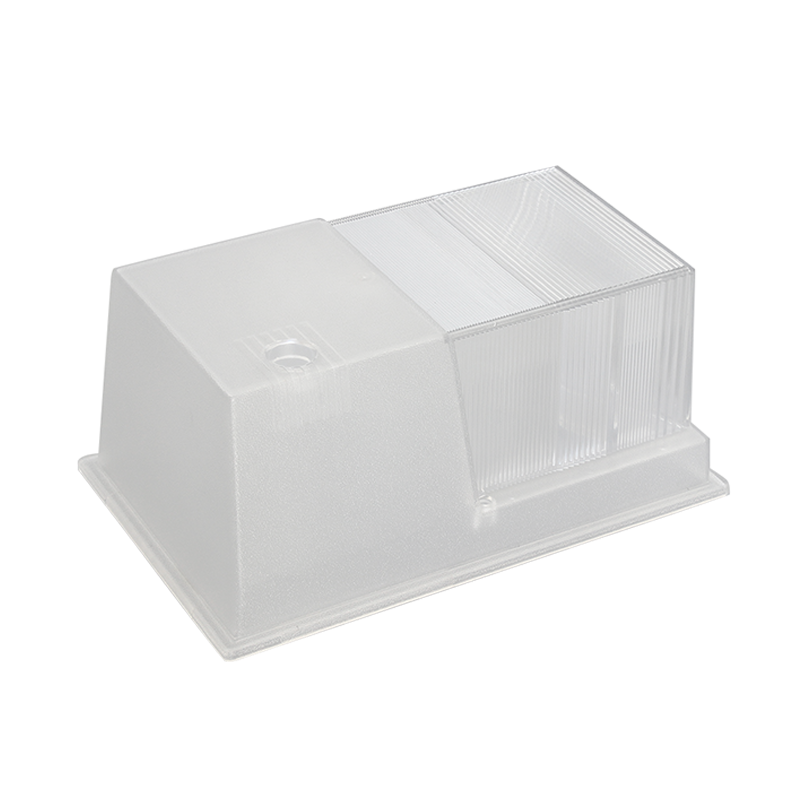

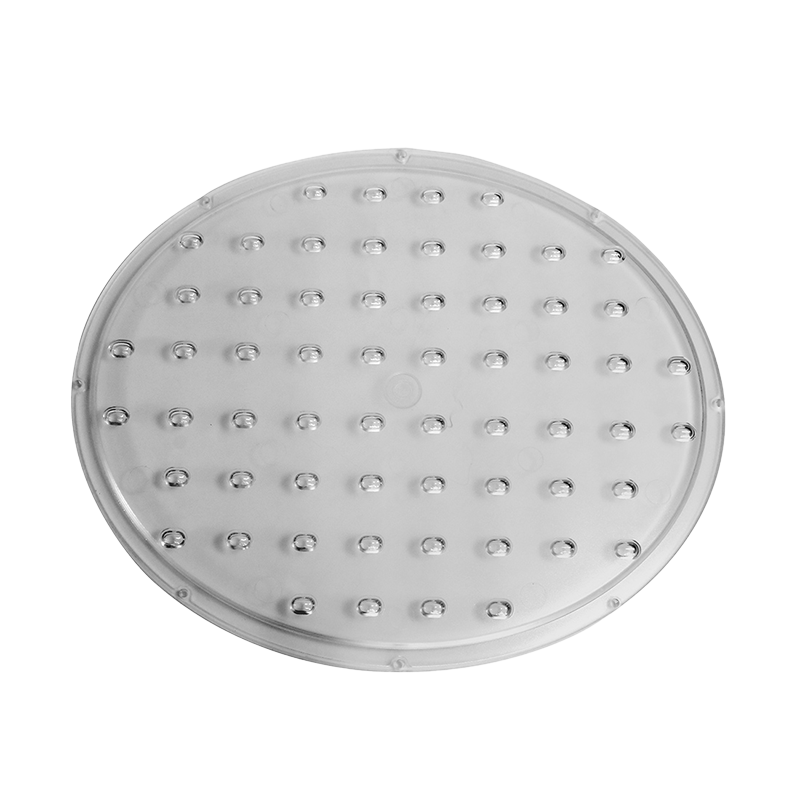

Complex Designs: Injection molding allows for the creation of intricate and detailed parts, which is essential for replicating the anatomy of a real dog. This technology enables manufacturers to produce lifelike fur textures, realistic facial features, and intricate joint mechanisms.

Precision and Consistency: Robots require precise movements and components. Injection molding ensures that each part is created with incredible accuracy, providing consistency and reliability in the manufacturing process. This precision results in a more reliable and stable robot dog.

Durability: Robot dogs need to withstand wear and tear, especially if they're intended for use in various environments. Injection molding produces robust parts that are highly resistant to damage, ensuring the longevity of these mechanical companions.

Cost-Effective: While producing complex components might sound expensive, injection molding is a cost-effective method for mass production. This efficiency translates into more affordable robot dogs for consumers.

Material Variety: Injection molding accommodates various materials, including plastics, metals, and even composites, providing manufacturers with a wide range of options for different components of the robot dog.

English

English Español

Español 简体中文

简体中文