In today's technology of increasing cognizance on sustainability, the sustainability dreams of injection molding era in the manufacturing of plastic lampshades have come to be even extra critical. This article will discover how sustainability dreams may be completed all through the injection molding manner, with a specific attention on the layout and manufacturing ranges of plastic lampshades to lessen resource consumption, lessen waste technology, and growth cloth recyclability.

Explore key selections in the course of the design section to decrease resource intake and waste era

Material Selection: During the design section, deciding on sustainable materials is critical. Use recyclable or biodegradable substances to lessen reliance on non-renewable sources.

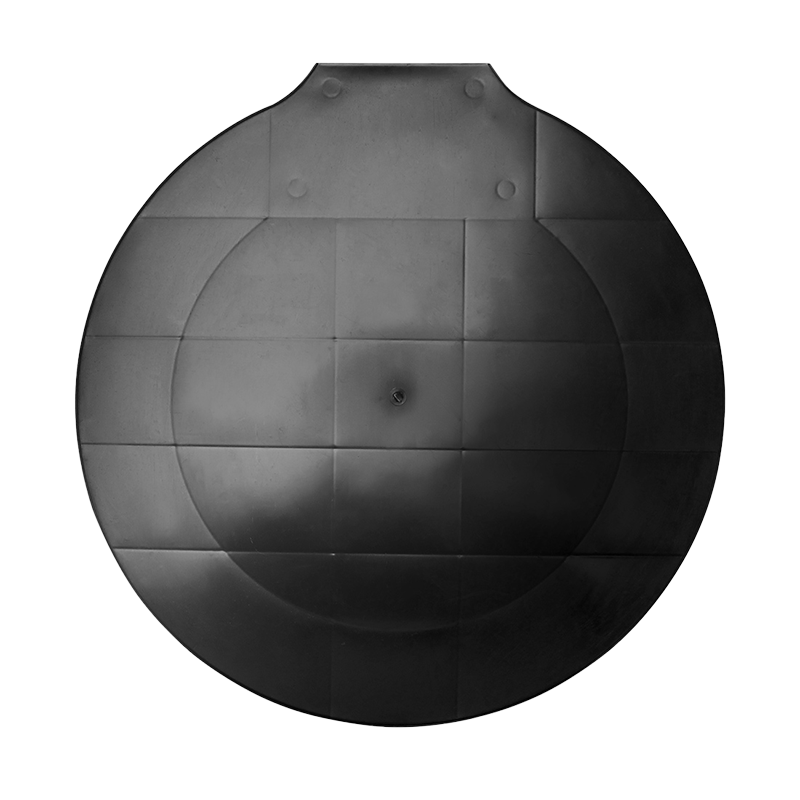

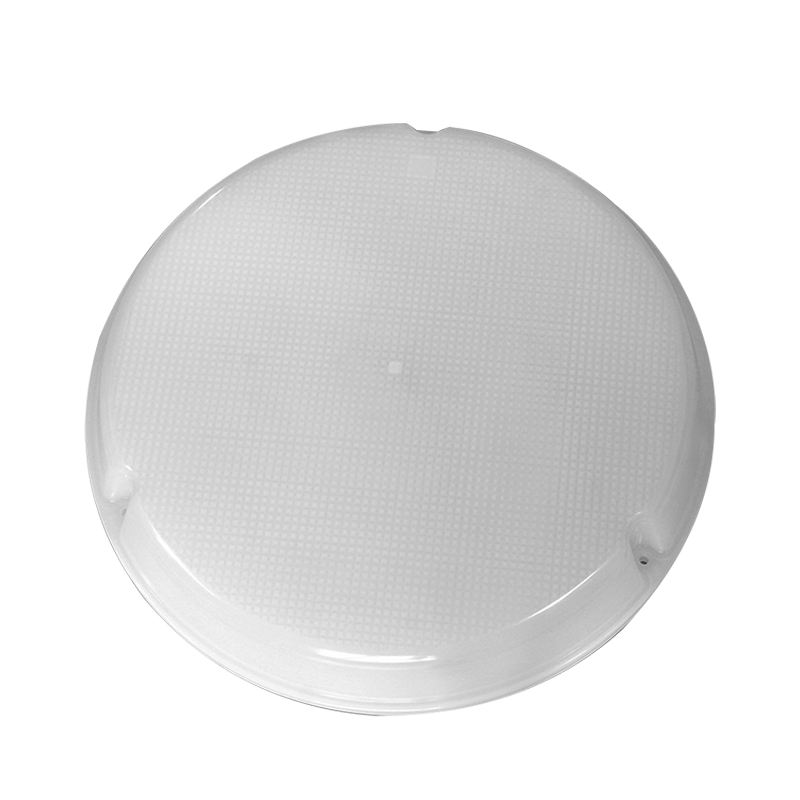

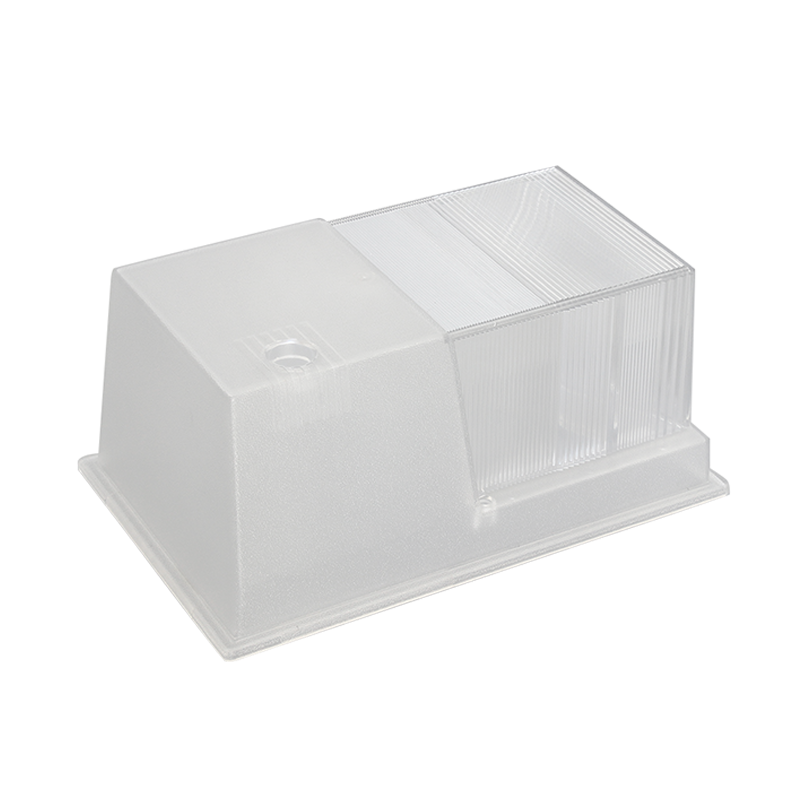

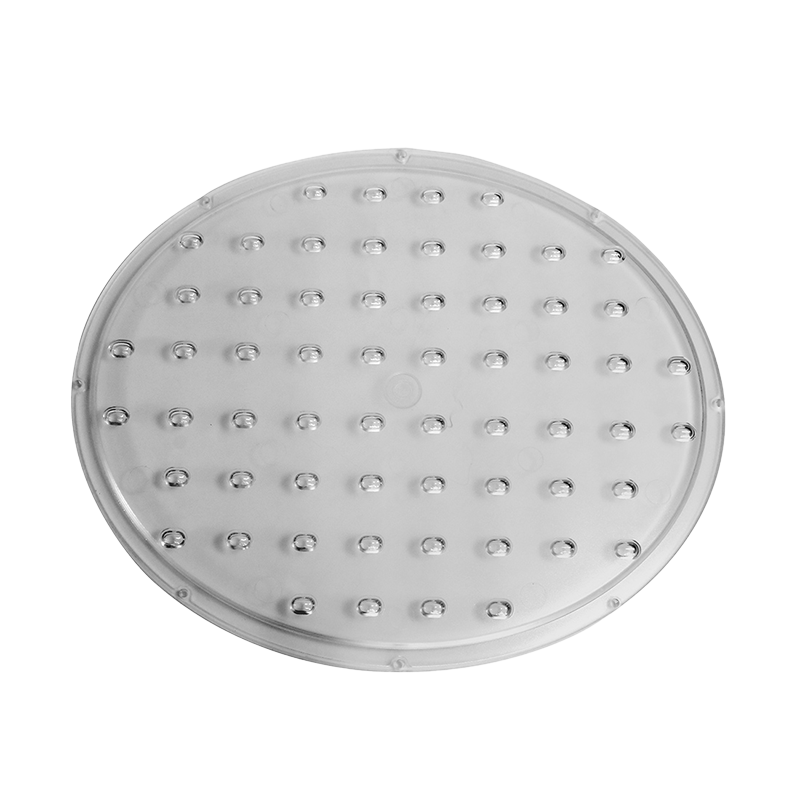

Design optimization: By optimizing the structure and shape of the lampshade, the quantity of fabric used is reduced while making sure the capability and beauty of the product. Adopt light-weight layout standards to lessen strength consumption in the course of manufacturing and transportation.

Mold design: Adopt multi-hollow space layout and modular shape to enhance mould usage and reduce strength intake and waste era for the duration of the producing technique.

Repairability and reusability: Consider the repairability of the product within the layout to increase the life of the product and decrease waste generated because of product scrapping. At the equal time, the layout of reusable lampshades is advocated to lessen aid intake.

Share a few sensible cases illustrating sustainable practices in production

Recycling of waste substances: During the manufacturing procedure, waste materials are sorted and recycled. Some advanced producers put into effect a round economy model and reprocess waste plastics into raw materials for new production.

Environmentally pleasant fabric utility: Use environmentally licensed plastic substances, which include biodegradable bio-primarily based plastics, to reduce the burden on the surroundings. Some groups even use recyclable substances to in addition sell environmental safety.

Energy management: Optimize production traces and adopt high-efficiency power equipment to lessen energy consumption within the production technique. Some corporations invest in easy strength, inclusive of solar or wind energy, to update conventional energy-in depth production methods.

Supply chain sustainability: Establish sustainable partnerships with suppliers, pick environmentally conscious companions, and make certain sustainable procurement of raw substances.

Quality control and technological innovation of plastic lampshade injection molding:

Quality control methods and technological innovation in injection molding

Real-time monitoring device: Introduce a real-time monitoring system to reveal key parameters inside the injection molding technique in actual time via sensors and facts analysis, which will find out and correct capability pleasant problems in a well timed manner.

Intelligent injection molding device: Use clever injection molding machines to improve manufacturing efficiency and reduce scrap fees via superior manipulate structures and algorithms, thereby decreasing the waste of assets.

3-D printing mold: The innovative use of 3-D printing era to fabricate injection molds can greater flexibly recognize the design of complicated systems and decrease material waste in the mold production procedure.

Production process optimization: Continuously optimize the injection molding manufacturing process and undertake strength-saving and green method parameters to improve product consistency and satisfactory stability.

The layout and manufacturing of sustainable injection molded lampshades is an inevitable trend for injection molding generation to meet future demanding situations. By decreasing aid consumption within the design level, the usage of environmentally pleasant substances, and recycling waste materials in production practices, the injection molding enterprise is predicted to make a extra contribution to environmental sustainability. Technical innovations in exceptional manipulate similarly ensure the performance and reliability of the production method. Under the concept of sustainable improvement, injection molding era will better meet market call for and promote the sustainable improvement of the enterprise.

English

English Español

Español 简体中文

简体中文