Today, with the increasing development of science and technology, the shell models (Instrument and Device Shell Model) of various instruments and equipment play a decisive role. Not only do they protect the delicate components inside, they also directly affect the overall performance and service life of the equipment. Among them, the material selection of the shell model is a crucial link, which is directly related to the reliability, safety and durability of the equipment.

The choice of material directly affects the strength and stiffness of the instrument and equipment housing. Some high-strength, high-rigidity materials, such as metal alloys or engineering plastics, can effectively resist external impact and extrusion, ensuring the stable operation of equipment in harsh environments. Some lightweight materials, such as carbon fiber or aluminum alloy, can reduce the overall weight while ensuring strength, making it easier to carry and install.

Material also has a significant impact on the thermal performance of the device. Some materials with good thermal conductivity, such as copper or aluminum, can quickly dissipate the heat generated inside to prevent equipment damage due to overheating. Some materials with good thermal insulation properties, such as ceramics or special plastics, can maintain the stability of the equipment in high or low temperature environments and prevent performance degradation caused by temperature changes.

In addition, the material also affects the friction and wear resistance of the device's shell surface. Some materials with excellent lubrication properties can reduce friction and reduce energy consumption and noise during equipment operation. Materials with good wear resistance can extend the service life of the equipment and reduce performance degradation or failure caused by shell wear.

Material selection also needs to consider its impact on electromagnetic performance. Some materials with good electrical conductivity, such as metal, can effectively shield external electromagnetic interference and ensure the stable operation of the equipment. Some materials with good insulation properties can prevent electromagnetic leakage inside the equipment and protect the safety of users.

Instrument and Device Shell Model material selection has a profound impact on performance. When selecting materials, multiple factors such as the device's purpose, working environment, performance requirements, and cost need to be comprehensively considered to ensure that the most suitable material is selected to maximize the performance and reliability of the device.

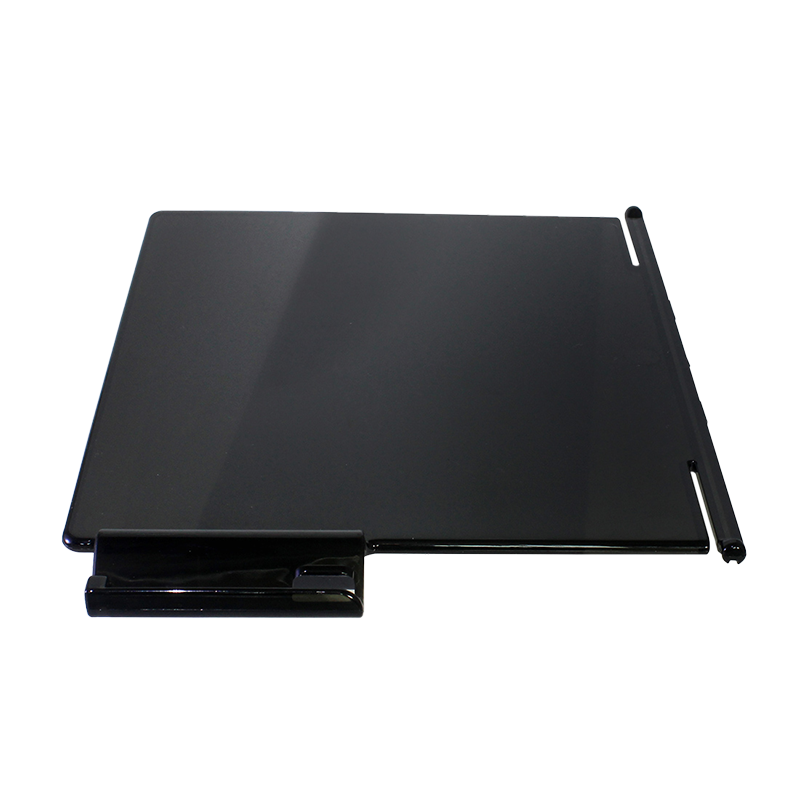

The impact of instrument and device shell model material selection on performance

Guarantee High Quality With Our Expertise

English

English Español

Español 简体中文

简体中文