ABS material has excellent mechanical properties, among which acrylonitrile provides high hardness and strength, styrene contributes good rigidity and dimensional stability, and butadiene gives the material excellent impact resistance. This combination makes the core opener less likely to break or deform when subjected to external forces, ensuring that it can maintain structural integrity during frequent use. For tool products that need to withstand certain mechanical loads, ABS's balanced performance makes it an ideal choice.

ABS exhibits good melt fluidity during injection molding, and can fill the fine structure of complex molds, ensuring that the product size is accurate and the surface is smooth. In addition, its low molding shrinkage reduces the risk of deformation after demolding, which helps to keep the core opener and the supporting parts tightly matched. This easy processing not only improves production efficiency, but also reduces the scrap rate, making it suitable for mass production.

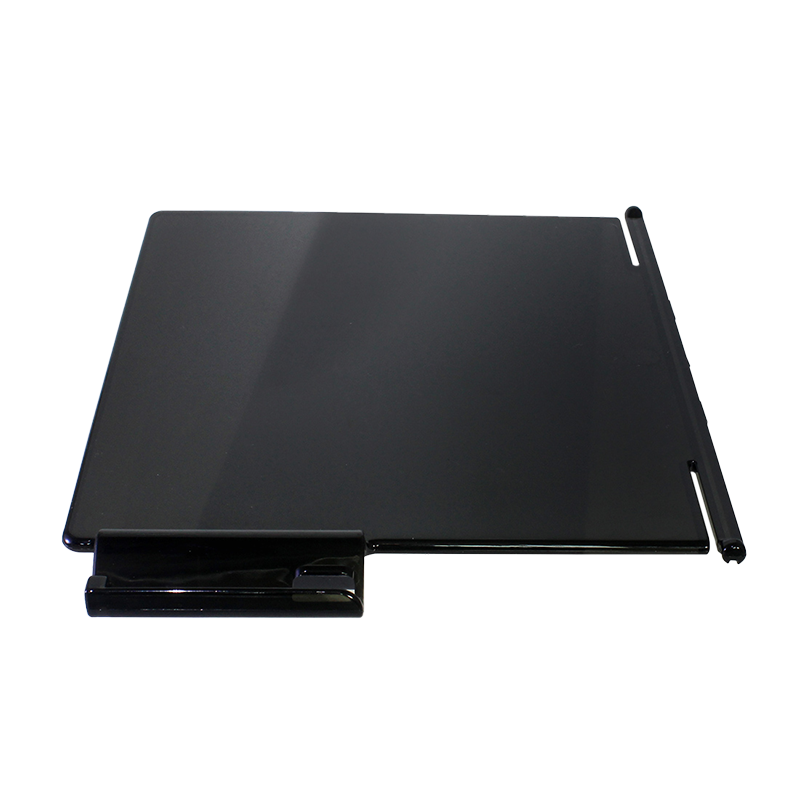

ABS material is easy to surface treat, such as polishing, painting, electroplating or UV coating, which can meet the high requirements of the core opener for appearance and touch. The ABS parts with smooth surface treatment have a delicate texture and a certain scratch resistance, and are not easy to show obvious wear even after long-term use. For tools that need to be both functional and aesthetic, the surface properties of ABS provide greater design flexibility.

ABS has a certain tolerance to common oils, detergents, and weak acids and alkalis, and is suitable for chemicals that core openers may come into contact with in industrial or daily environments. Its operating temperature range covers most application scenarios, ensuring normal use in cold or normal temperature environments. However, ABS may age when exposed to ultraviolet rays or high temperatures for a long time. At this time, weather resistance can be improved by adding anti-UV agents or selecting modified materials.

Compared with other engineering plastics, ABS has a lower raw material cost and a mature injection molding process, which can effectively control production costs and is suitable for products such as core openers that require large-scale production. In addition, ABS can be recycled and reused, and waste and scraps can be crushed and granulated to reduce resource waste, which is in line with the production concept of sustainable development.

English

English Español

Español 简体中文

简体中文